In the world of industrial separation processes, efficiency is key. Whether you’re in the pharmaceutical, food and beverage, chemical, or oil and gas industry, achieving optimal separation of liquids and solids is essential for smooth operations and high-quality end products. One technology that has revolutionized this process is the tubular bowl centrifuge.

In this article, we will delve deep into the structure, working principles, applications, and features of tubular bowl centrifuges, shedding light on how this remarkable piece of machinery can transform your industrial processes. Moreover, we’ll highlight SEPARATECH as a leading provider of high-quality tubular bowl centrifuges, giving you the edge you need in your business operations.

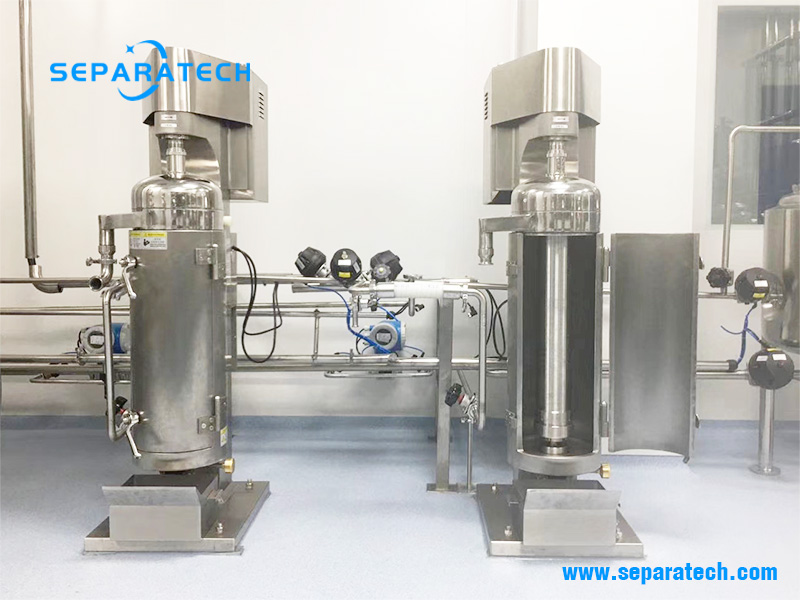

The Anatomy of a Tubular Bowl Centrifuge

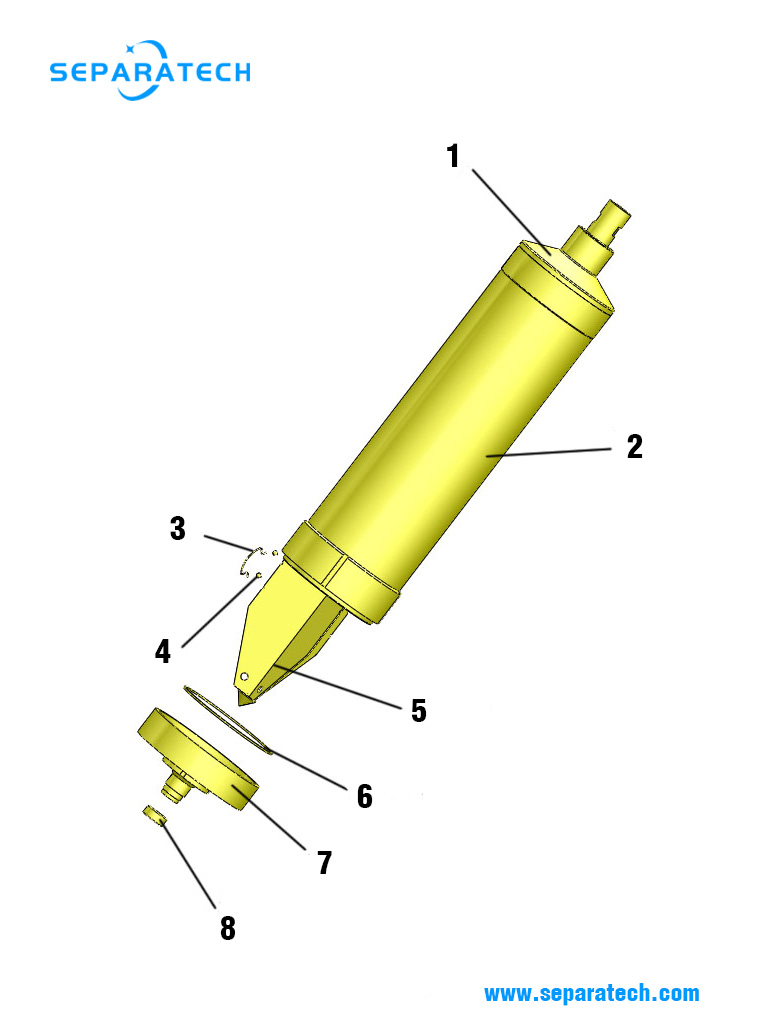

Before we dive into the applications and benefits, it’s crucial to understand the inner workings of a tubular bowl centrifuge. At its core, this marvel of engineering consists of three main components:

1. Bowl Assembly: The heart of the centrifuge, the bowl assembly, is where the magic happens. It consists of a cylindrical bowl with a conical bottom and a spinning rotor inside. The bowl is typically made of high-grade stainless steel, ensuring durability and corrosion resistance.

2. Drive System: Connected to the bowl assembly is the drive system, which imparts rotational motion to the bowl. This system ensures that the contents within the bowl are subjected to high gravitational forces, promoting efficient separation.

3. Control Panel: Modern tubular bowl centrifuges come equipped with advanced control panels that allow operators to fine-tune the separation process. These panels enable precise control of rotational speed, feed rates, and discharge settings.

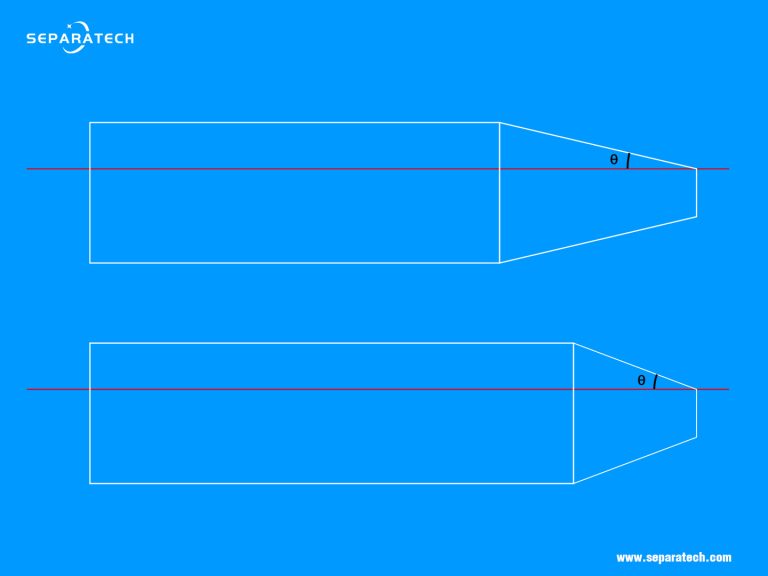

The basic structure of a tubular bowl centrifuge consists of a cylindrical bowl, a spindle, a motor, and a feed pipe. The bowl rotates at a high speed around the spindle, which is driven by the motor. The feed pipe introduces the mixture into the bowl, where it is subjected to the centrifugal force. Depending on the density difference between the phases, the heavier phase moves to the wall of the bowl, while the lighter phase stays near the center. The separated phases are then discharged through different outlets at the bottom of the bowl.

There are two main types of tubular bowl centrifuge: 2-phase and 3-phase. A 2-phase tubular bowl centrifuge separates a solid-liquid into two phases. A 3-phase tubular bowl centrifuge separates a solid-liquid-liquid mixture into three phases.

Tubular bowl centrifuge working principle

Tubular bowl centrifuge operate on the principles of centrifugal force and density difference, including GQ and GF series.

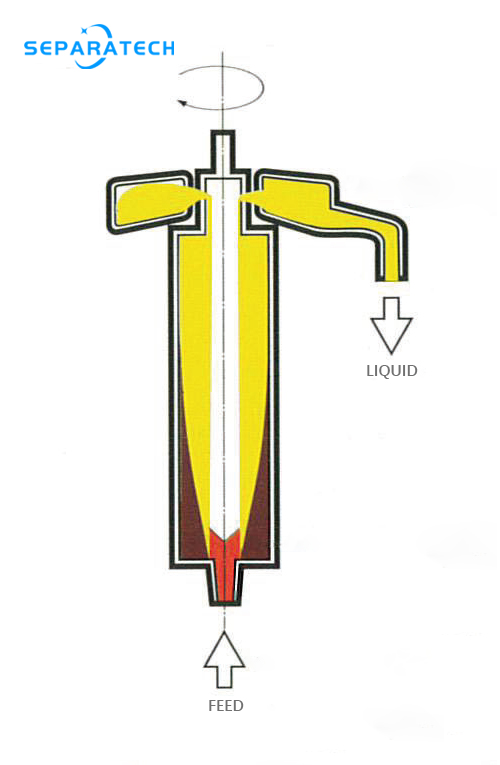

GQ 2-phase tubular centrifuge

GQ series is mainly used for 2-phase separation. A 2-phase tubular bowl centrifuge is a device that can separate a mixture of two different phases: liquid phase and solids phase.

The working principle of a 2-phase tubular bowl centrifuge is based on the difference in specific gravity and centrifugal force of the two phases. The suspension is fed into the bottom of a rotating bowl, where it is accelerated to a high speed.

The solid phase, which has the heavier specific gravity, is pushed to the inner wall of the bowl and forms a cake layer.

The liquid phase, which has the lower specific gravity, forms an inner layer, and remains closer to the bowl center.

The two phases are then discharged separately from different outlets: the solid phase is manually removed from the bowl after stopping the centrifuge; the liquid phase is discharged from the top of the centrifuge.

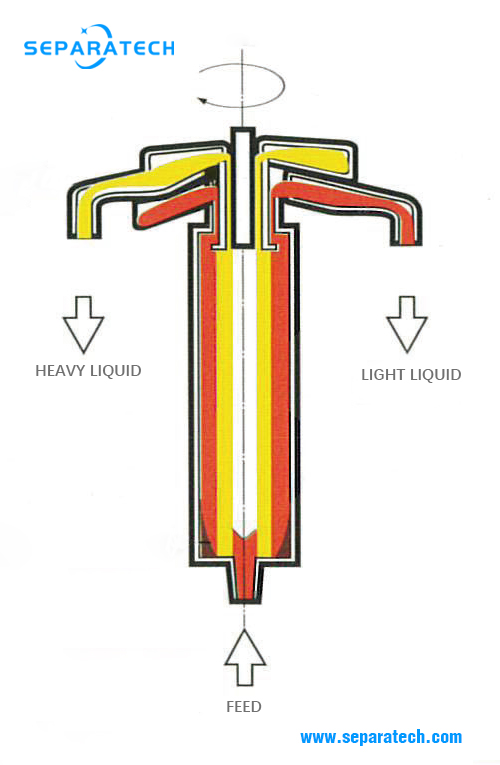

GF 3-phase tubular centrifuge

GF series is mainly used for 3-phase separation. A 3-phase tubular bowl centrifuge is a device that can separate a mixture of three different phases: a heavy liquid, a light liquid, and a solid.

The working principle of a 3-phase tubular bowl centrifuge is based on the difference in specific gravity and centrifugal force of the three phases. The mixture is fed into the bottom of a rotating bowl, where it is accelerated to a high speed.

The solid phase, which has the highest specific gravity, is pushed to the inner wall of the bowl and forms a cake layer.

The light liquid phase, which has the lowest specific gravity, forms an inner layer near the axis of the bowl.

The heavy liquid phase forms an intermediate layer between the light liquid and the solid phases.

The three phases are then discharged separately from different outlets: the solid phase is manually removed from the bowl after stopping the centrifuge; the light liquid phase and heavy liquid phase are discharged from the top of the centrifuge.

Applications of Tubular Bowl Centrifuges

Tubular bowl centrifuges find applications in a wide range of industries, thanks to their versatility and efficiency. Some key applications include:

– Pharmaceutical Industry: Separation of active pharmaceutical ingredients (APIs) from fermentation broths and cell cultures.

– Food and Beverage Industry: Clarification of fruit juices, vegetable oils, and the separation of yeast from beer.

– Chemical Industry: Purification of chemicals, separation of catalysts, and recovery of valuable products.

– Oil and Gas Industry: Dewatering of crude oil, separation of water from fuel, and removal of solid impurities.

– Environmental Sector: Treatment of wastewater, sludge dewatering, and the separation of pollutants.

Features That Set Tubular Bowl Centrifuges Apart

SEPARATECH, a trusted name in the centrifuge industry, offers high-quality tubular bowl centrifuges that come with several noteworthy features:

1. Robust Construction:

SEPARATECH centrifuges are built to withstand harsh industrial environments, ensuring long-term durability and reliability.

2. Easy Maintenance:

Designed with user-friendliness in mind, these centrifuges are easy to maintain, reducing downtime and operational costs.

3. Customization:

SEPARATECH provides customized solutions to match your specific separation needs, ensuring optimal performance.

4. Advanced Control:

Their centrifuges are equipped with advanced control systems, allowing precise adjustment of process parameters for maximum efficiency.

5. Environmental Compliance:

SEPARATECH centrifuges are designed to meet environmental regulations, making them an eco-friendly choice for your operations.

In conclusion, tubular bowl centrifuges are a game-changer in industrial separation processes. They offer unparalleled efficiency and reliability across a multitude of industries. When considering a tubular bowl centrifuge for your operations, SEPARATECH stands out as a trusted provider, offering top-quality solutions that can elevate your business to new heights.

Invest in the power of tubular bowl centrifuges and experience a transformation in your industrial processes. Contact SEPARATECH today to explore their range of centrifuge solutions tailored to your needs, and take the first step towards enhanced productivity and profitability.