Tubular Bowl Centrifuge

Tubular bowl centrifuge is a kind of centrifugal separation equipment with high separation factor, which is mainly used for solid-liquid separation and liquid-liquid-solid separation of industrial materials. Tubular bowl centrifuge has good separation effect, high output, small footprint and convenient operation. It is especially suitable for solid-liquid separation with low concentration, high viscosity, fine solid particles and small difference in specific gravity between solid and liquid.

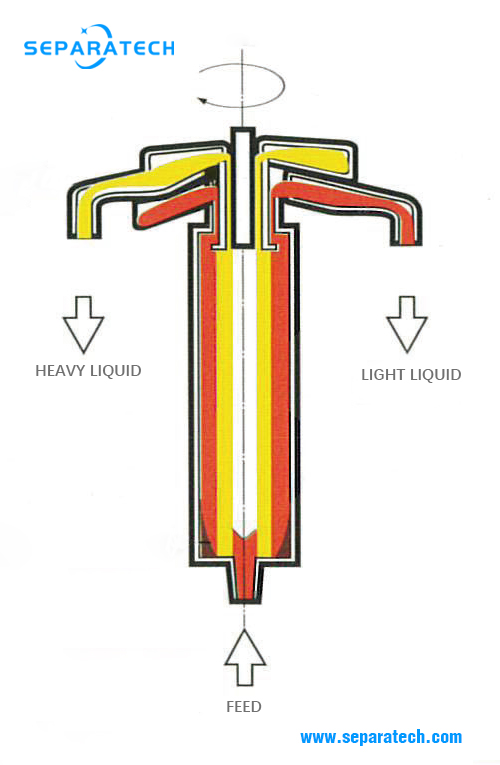

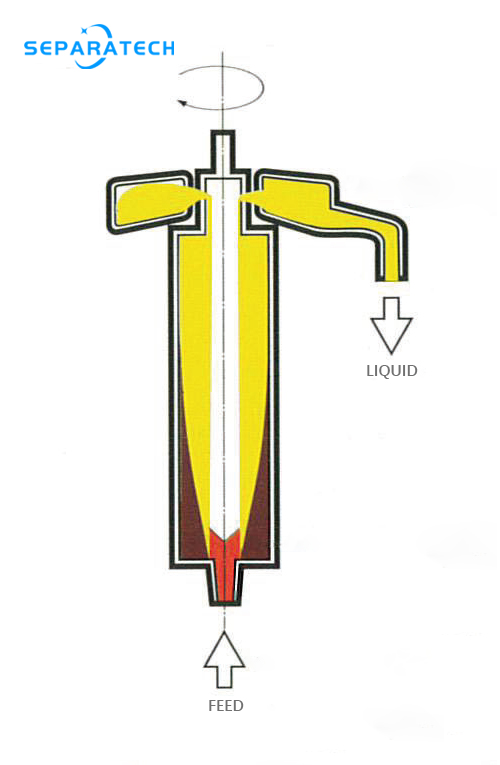

There are two main series of tubular bowl centrifuge, GF and GQ. GF is 3-phase for liquid-solid-liquid separation; GQ is 2-phase for solid-liquid separation.

GF Tubular Bowl Centrifuge Working principle: The motor transmits the power to the driven wheel through the transmission belt and the tension wheel, so that the bowl rotates around its own axis at high speed, forming a strong centrifugal force field. The material enters the drum from the liquid inlet at the bottom. Under the action of the centrifuge, the liquid phase with high density forms an outer ring, and the liquid phase with a low density forms an inner ring, and flows to the respective liquid outlets on the upper part of the bowl to be discharged. Trace solids It is deposited on the wall of the bowl and is manually discharged after the machine is shut down.

GQ Tubular Bowl Centrifuge working principle: it is composed of body, transmission device, bowl, and liquid-inlet bearing seat of the liquid collection plate. The upper part of the bowl is a flexible main shaft, and the lower part is a damping floating bearing. Through the transmission belt, the tension pulley transmits the power to the passive pulley, so that the bowl rotates around its own axis at high speed, forming a strong centrifugal force field, and the material enters from the liquid inlet at the bottom. Under the action of centrifugal force, the solid phase particles in the liquid phase Since the density is greater than that of the liquid phase, it gradually moves to the inner wall of the bowl to form a sediment layer, and the clarified liquid is discharged from the upper discharge port. When the thickness of the sediment layer affects the clarity of the liquid phase, or reaches the rated slag capacity of the bowl, manually remove the sediment on the bowl wall after shutdown.

Features

Ultra-High separation factor

Continuous processing

Two phase (liquid/solid) separation

Three phase (liquid/solids/liquid) separation

High recovery of sludge

Water jacketed cooling system (optional)

Rotate speed adjustable (optional)

Intuitive touch-screen control panel

Robust design and shock proof operation

Applications

– Pharmaceutical

Collection of pharmaceutical intermediates, herb extracts, plant fibers and chlorella

– Food processing

Soy bean, fat, vegetable oil, starches, grains, gelatin, amino acids, soy sauce, reducing fat in milk

– Waste water treatment

Cleaning on straining waste water, leather waste water, petroleum tank sludge, waste oil

– Chemistry industry

Cleaning and collection of ink, paints, ammonia, barium, aluminum, zinc, activated charcoal and stainings

– The other fields

Milk fat processing, cosmetics, cod-liver oil, yeast processing, and many other separations of solution and collection of solids

GQ Tubular Bowl Centrifuge Specifications

| Designation | Bowl ID | Bowl Volume | Bowl Speed | G-force | Hydraulic capacity | Motor | Weight | Dimension |

|---|---|---|---|---|---|---|---|---|

| mm | L | r/min | g | L/h | kw | kg | mm | |

| GQ76 | 76 | 2 | 20000 | 17000 | 200 | 1.5 | 180 | 650*380*1150 |

| GQ105 | 105 | 6 | 16000 | 15000 | 1200 | 3 | 550 | 800*450*1620 |

| GQ142 | 142 | 11 | 17000 | 23000 | 2000 | 3 | 950 | 910*620*1770 |

GF Tubular Bowl Centrifuge Specifications

| Designation | Bowl ID | Bowl Volume | Bowl Speed | G-force | Hydraulic capacity | Motor | Weight | Dimension |

|---|---|---|---|---|---|---|---|---|

| mm | L | r/min | g | L/h | kw | kg | mm | |

| GF105 | 105 | 6 | 16000 | 15000 | 1200 | 3 | 550 | 800*450*1620 |

| GF142 | 142 | 11 | 17000 | 23000 | 2000 | 3 | 950 | 910*620*1770 |