Horizontal Pressure Leaf Filter

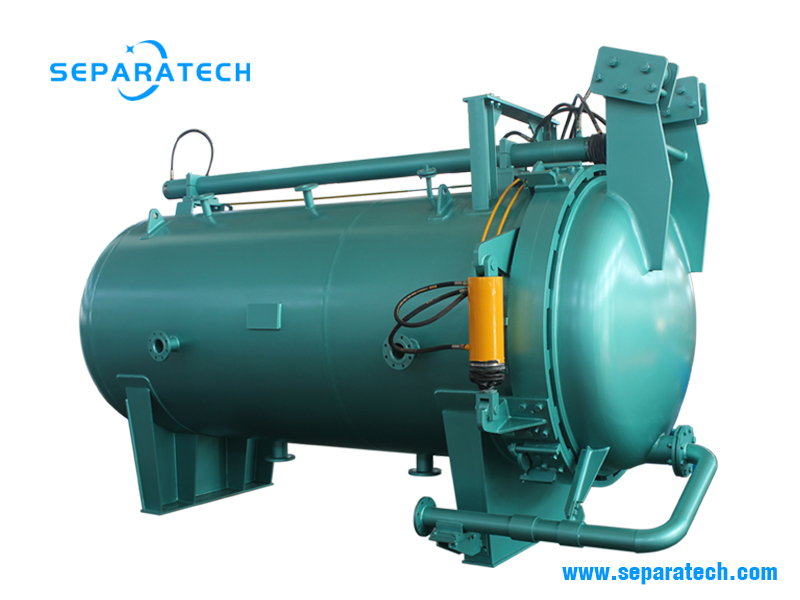

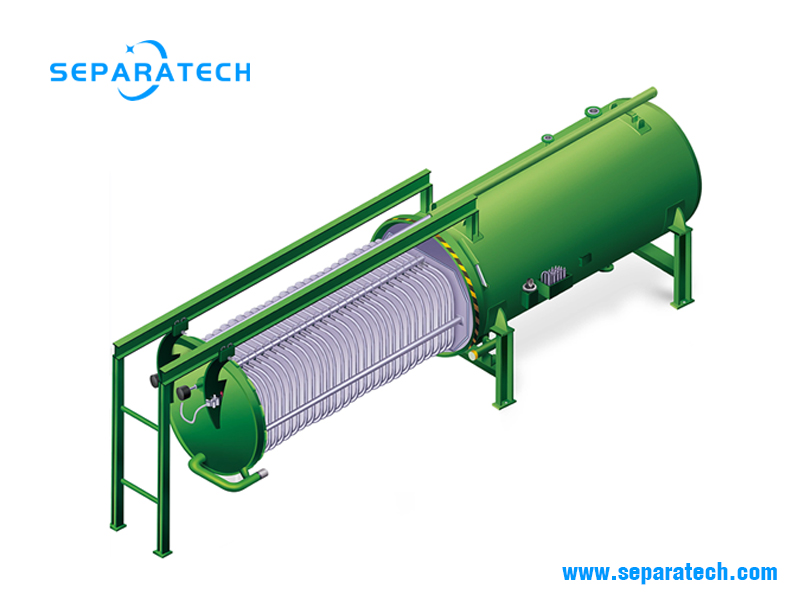

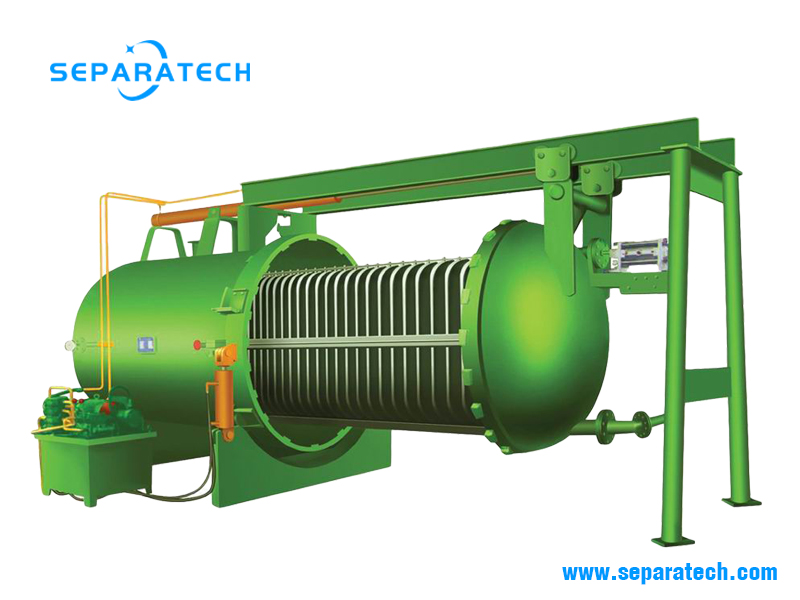

Horizontal Pressure Leaf Filter (shell retraction or bundle retraction) features horizontal pressure vessel, filter leaves, pneumatic vibrator assembly, bottom structure housing, hydraulic power pack for bonnet ring opening / closing and shell or bundle retraction.

The horizontal vessel orientation is the most common type of pressure leaf filter. This arrangement allows for the greatest filtration area. Vessel sizes are available up to 2000mm in diameter providing up to 200 m2 of filtration area. All horizontal filters use vertical filter leaves. Our filters are custom built & optimized for each application, and are specifically engineered to operate with the minimum amount of maintenance.

The horizontal pressure leaf filter is an enclosed filtration system and can be fully automated. This filter produces a high filtrate clarity after the clarification run and is also suitable for all kinds of filter aids. The regeneration time between the filtration cycles is short. Horizontal pressure leaf filters can also be delivered as tandem units to save floor space. The pressure leaf filter itself has no rotating parts, keeping maintenance to a minimum. These advantages result in an economical filtration solution.

Horizontal pressure leaf filter working principle

Leaf Filters are ideal for solid-liquid separation and work on principle of precoating and pressure.

Pre-coating is done with the help of suitable filter aid about 0.5 to 1% (Bleaching earth, diatomite, activated carbon, etc.) mixed with the liquid to be filtered. Unfiltered liquid is pumped into the filter vessel. Initially the filter aid starts forming a precoat layer on both sides of the filter leaves, until then cloudy material comes out of the filter. Once the layer is formed, pressure starts developing, restricting the impurities. Clear liquid flows from both sides into the leaves (filter elements), flows along the tubular channel & gets discharged from bottom of the leaf. All the leaves are mounted on a common manifold. The leaves start getting choked on both the sides by impurities forming cake, which is in wet from. Once the leaves get choked completely, the pressure rises to 3 kg/cm2 & the output flow almost stops. This means the batch size is reached. The pump is stopped & steam / air pressure is applied from the top (without dropping the filter pressure) to filter the material around the leaves held up in the tank & to squeeze the cake further & reduce the liquid retention in it. The holdup unfiltered liquid in the conical portion is taken back.

Horizontal pressure leaf filter construction

Horizontal pressure leaf filter works on similar principal of vertical type but shell is horizontal and leaves are vertical on common manifold. The filter shell has 4 wheels & can be retractable by a hydraulic cylinder on a rail. Two hydraulic cylinders are provided one each for opening and closing the wedge lock mechanism between the shell and cover. A hydraulic power pack unit, pressure gauge, vent or steam valves, panel board etc. are provided. After the filtration and cake drying is over, the outer vessel is retracted, thus opening up the leaves for cake discharge. During opening and cleaning no connections have to be removed as the cover with leaves remain in fixed position.

Cake can either be discharged manually by rubber mallet or optionally pneumatic / mechanical vibration can be provided for dry cake discharge. Spray nozzles can be provided for wet cake discharge. Horizontal pressure leaf filter is preferred for higher filtration area, higher cake capacity or when solid cake is sticky and has to be removed manually in semi dry condition and in short period.

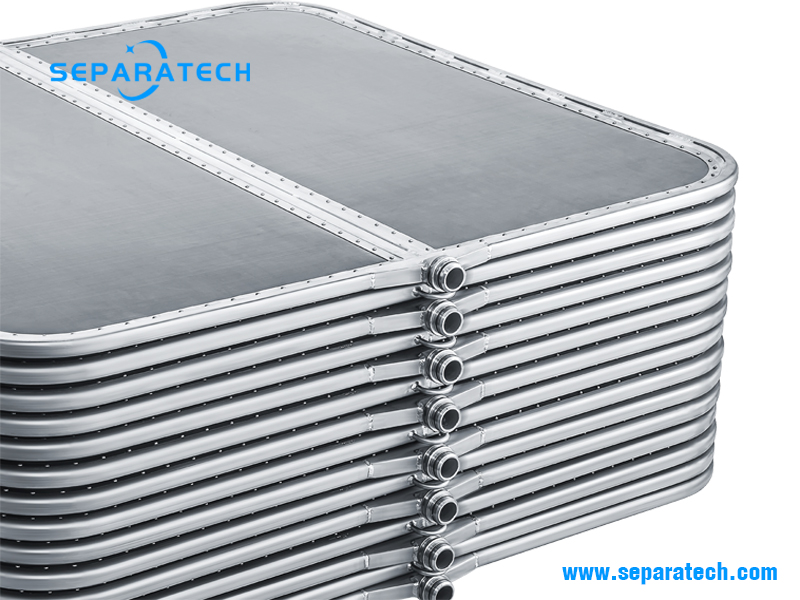

Filter leaf construction

Each leaf is made of 5-ply of SS wire mesh of different gauge wires. Two outer filtering mesh and three inners are only for support. Different outer filtering mesh is used for different filtration process. The 5-ply wire mesh are held together by a tubular frame and made leak proof by machine riveting. The quality of filtration and life of filter depends mainly on the quality of outer wire mesh and revetting. SEPARATECH ensure the quality by inspecting quality of wire mesh and each leaf. Old worn out and torn leaves can be repaired by only replacing the outer weave. Optionally we also provide cloth on the leaves for fine or special filtration.

Horizontal pressure leaf filter applications

– Edible oil Industry:

Bleached, winterized, deodorized, hydrogenated, fractionated oil, dewaxing, catalyst, mineral oil.

– Beverage Industry:

For glucose, fruit juice, cold drinks, sugar, vinegar.

– Chemical Industry:

For organic & inorganic salts, dyes, chemicals, plasticizers, sulphur, copper.

– Pharma Industry:

For pharmaceutical, intermediates, syrup, bulk drugs, antibiotics, intravenous solution.

– Petrochemical Industry:

Crude oil, LPG, lubricating oil, sulphur.

Specifications

| designation | filtering area m2 | no. of leaves | leaf spacing mm | diameter mm | vessel vol. L | footprint mm |

|---|---|---|---|---|---|---|

| HPLF15 | 15 | 20 | 80 | 900 | 1.5 | 6200X2000 |

| HPLF20 | 20 | 26 | 80 | 900 | 1.8 | 6800X2000 |

| HPLF25 | 25 | 21 | 90 | 1200 | 2.7 | 6400X2300 |

| HPLF30 | 30 | 25 | 90 | 1200 | 3.4 | 6800X2300 |

| HPLF35 | 35 | 20 | 100 | 1400 | 4.5 | 7100X2500 |

| HPLF40 | 40 | 19 | 100 | 1500 | 4.8 | 7000X2600 |

| HPLF45 | 45 | 18 | 110 | 1600 | 6.4 | 7200X2800 |

| HPLF50 | 50 | 20 | 110 | 1600 | 6.5 | 7400X2800 |

| HPLF60 | 60 | 24 | 110 | 1600 | 6.8 | 7800X2800 |

| HPLF70 | 70 | 22 | 110 | 1800 | 8.2 | 7600X3000 |

| HPLF80 | 80 | 25 | 110 | 1800 | 8.7 | 8000X3000 |

| HPLF90 | 90 | 28 | 110 | 1800 | 9.2 | 8400X3000 |

| HPLF100 | 100 | 31 | 110 | 1800 | 9.7 | 9200X3000 |

| HPLF120 | 120 | 28 | 120 | 2000 | 12.5 | 9800X3400 |

| HPLF140 | 140 | 36 | 120 | 2000 | 15.5 | 12000X3400 |

| HPLF160 | 160 | 36 | 120 | 2000 | 15.5 | 12000X3400 |

| HPLF180 | 180 | 36 | 120 | 2000 | 15.5 | 12000X3400 |

| HPLF200 | 200 | 36 | 120 | 2000 | 15.5 | 12000X3400 |