Pressure Leaf Filter

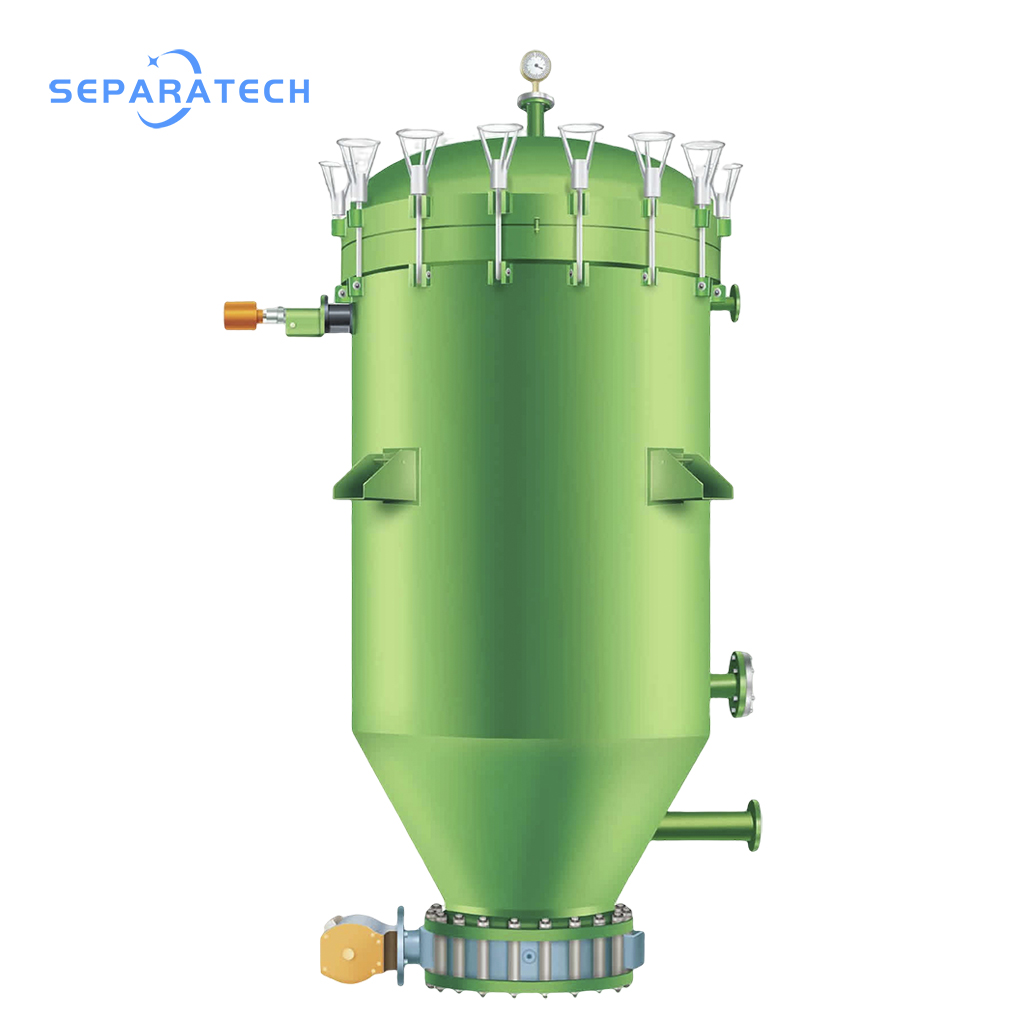

Pressure Leaf Filter is a MS/SS Vertical / Horizontal Vessel with Filter Leaves inside. The leaves are mounted vertically on a common manifold pipe, through which the filtered liquid flows out. On the top, the leaves are held by a vibrating shaft. A mechanical vibrator driven by electric motor/pneumatic vibrator is provided for vibrating the leaf shaft for cake discharge. Jacket for hot filtration can be offered if desired Over flow, vent/steam/air charging, pressure gauge & safety valve are provided on the top.

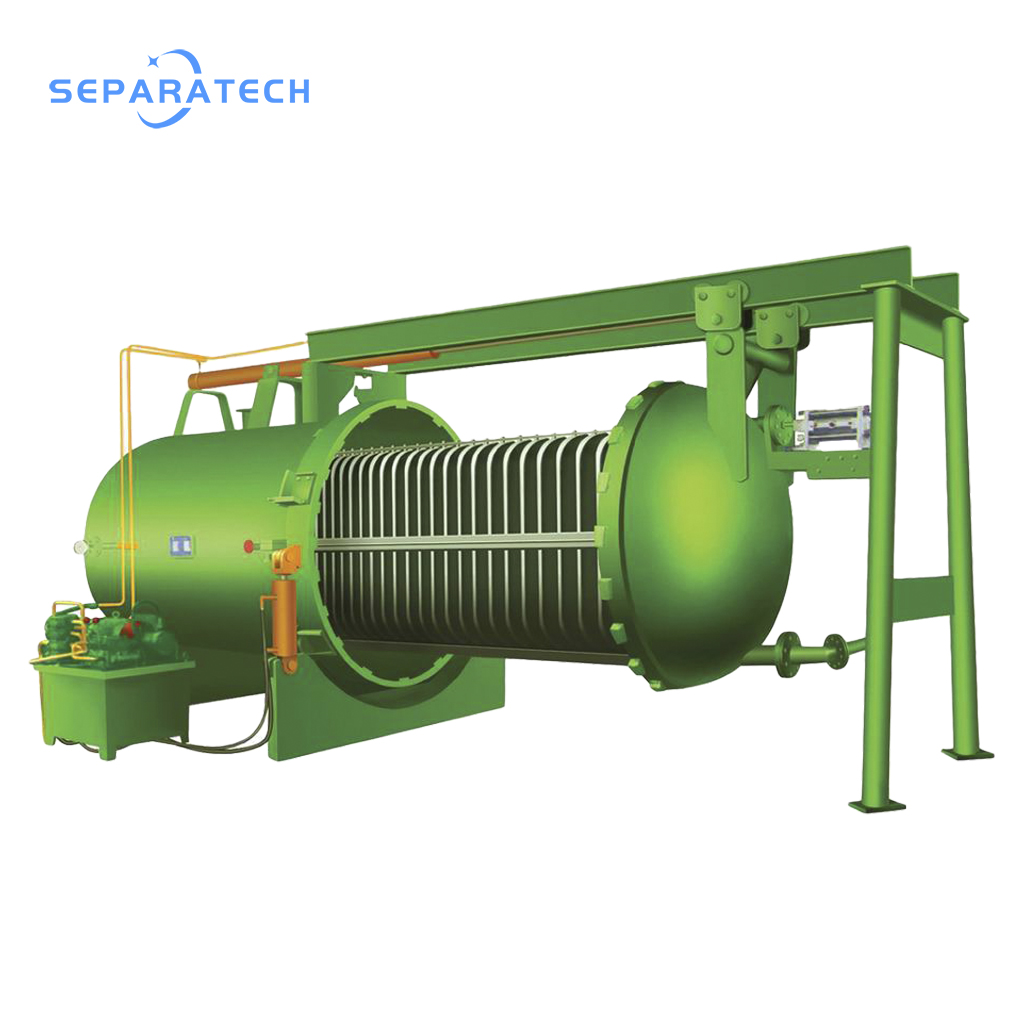

Pressure leaf filter is liquid filtration system consisting of 9 to 70 leaf-shaped filter elements that are stacked inside a vertical or horizontal vessel.

Vertical pressure leaf filter

Pressure leaf filter advantages and disadvantages

A pressure leaf filter is a type of filter that uses a stack of filter leaves inside a pressure vessel to separate solids from liquids. Some advantages of pressure leaf filters are:

– Pressure leaf filter can produce cakes with very low moisture content.

– Pressure leaf filter can filter very fine particles (0.5 to 1 micron) with the help of a precoat layer.

– Pressure leaf filter can be accessed easily and washed manually if needed.

Some disadvantages of pressure leaf filters are:

– Pressure leaf filter are suitable only for dilute solutions (less than 5% solids) and batch processes.

– Pressure leaf filter require high headroom for dismantling the leaves on vertical vessels.

– Pressure leaf filter may need frequent replacement of the filter cloth or mesh.

– Pressure leaf filter may clog easily if the precoat layer is not maintained properly.