Peeler Centrifuge

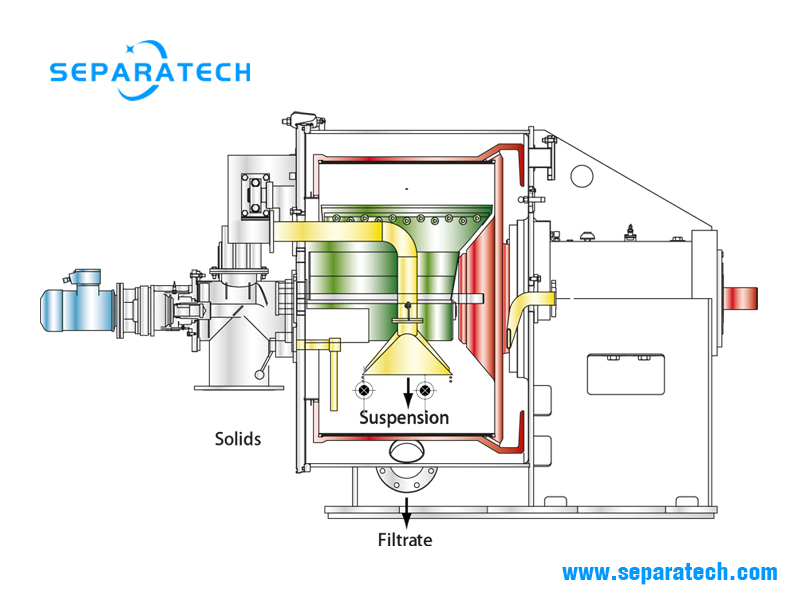

Peeler centrifuge is a device that performs by rotating filtration basket in an axis. A centrifuge follows on the principle of centrifugal force to separate solids from liquids by density difference. High rotation speed provides high centrifugal force that allows the suspended solid in feed to settle on the inner surface of basket.

There are mainly two kinds of centrifuge, horizontal, and siphon peeler centrifuge. These classes of instrument apply to various areas such as fertilizers, pharmaceutical, plastics and food including artificial sweetener and modified starch.

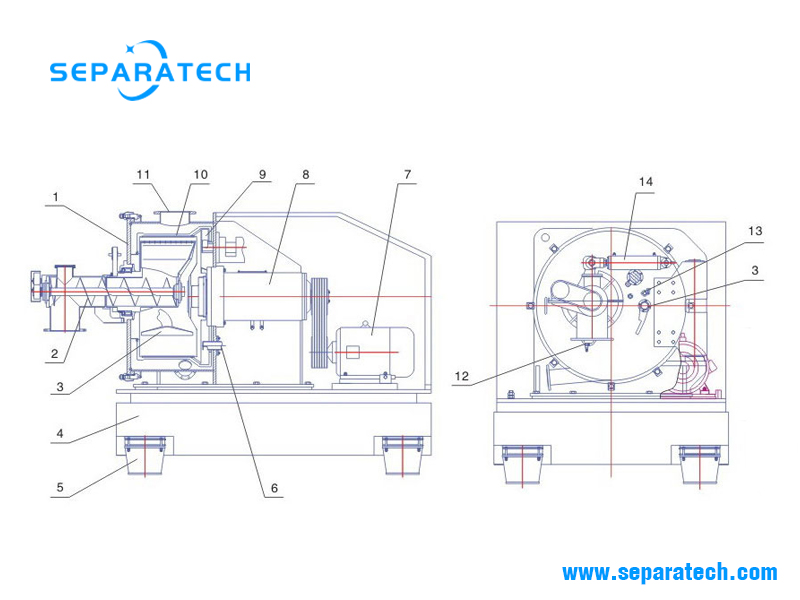

Main structure

1 Hood

2 Screw conveyor

3 Feeding pipe

4 Floating platform

5 Vibration isolator

6 Back washing device

7 Main motor

8 Transmission assembly

9 Siphon

10 Basket assembly

11 Vent pipe

12 Cake layer controller

13 Washing pipe

14 Oil cylinder of scraper

Peeler centrifuge operation

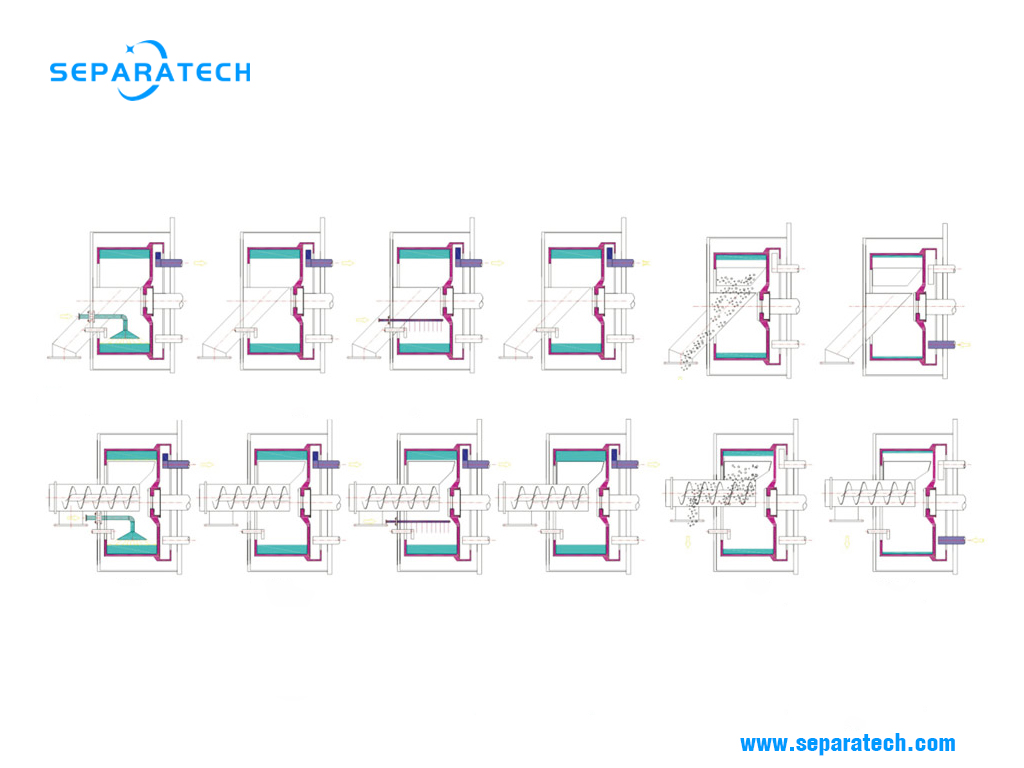

Feeding

The suspension is introduced into the rotating centrifuge basket via the feed distributor. Typically, this would include several intermittent feed pulses to prevent the suspension from spilling over the basket rim. The fill level is monitored and regulated by a feed controller. Normally, the basket is filled with solids up to 75-80% of the basket rim height. The feed step is complete when the filter cake has reached the desired level.

Filtration

Primary filtration of the raw material through the filter medium installed in the basket begins with the feed step and ends when the liquor has submerged into the filter cake. The solids retained on the filter medium after completion of a cycle and discharge of product serve as a filter medium for subsequent cycles.

Washing

A cake wash step will often follow the primary filtration step. Wash liquid is introduced through the feed distributor or, for lower wash rates, through a separate spray bar. The wash liquid level is again monitored by the feed controller and the wash step is concluded once the predetermined amount of wash liquid has been used and the liquid submerges into the filter cake.

Dry spinning

Immediately following the feed and wash step, which may be carried out at a lower speed, the basket is accelerated to maximum allowable speed for the cake dry spinning step which ends when the desired residual cake moisture is reached, or after a predetermined spin time.

Cake discharge

At the end of each centrifuge cycle, the filter cake is removed from the basket by a pivoting peeling device equipped with a broad peeler knife. Depending on the product characteristics, the peeling motion is conducted at full or reduced basket speed with adjustable swivel advance velocity. The scraped layers of product are diverted into a trough and discharged from the centrifuge through an inclined chute or a horizontal screw conveyor. To protect the filter medium, a thin layer of filter cake is retained in the basket. This layer, called the residual heel, becomes the filter aid for subsequent cycles.

Back washing

With the rotary siphon basket it is possible to feed backwash liquid from an overhead mounted prime tank through the siphon chamber to permeate the residual heel from underneath. This process re-suspends the residual heel and restores its permeability. It also primes the rotary siphon for the next filtration cycle. The liquid pool on top of the heel created through backwashing will assist in evenly distributing the subsequent cycle’s incoming suspension, which will virtually eliminate the potential for imbalances during the feed step.

Typecal applications

– Bulk chemicals

Petrochemical intermediates, fertilizers, chlorides, sulfates, calcium

compounds, sodium compounds

– Fine chemicals

Aluminum fluoride, amino acids, bleaching agents, surfactants, herbicides, pesticides, catalysts, dyestuffs

– Pharmaceuticals

APIs, vitamins, salicylic acid, citric acid, ascorbic acid, calcium citrate,

antibiotics

– Plastics

ABS, resins, melamine, PE, PP, antioxidant agents

– Foodstuff

Native and modified starches, artificial sweeteners, vanillin, caffeine

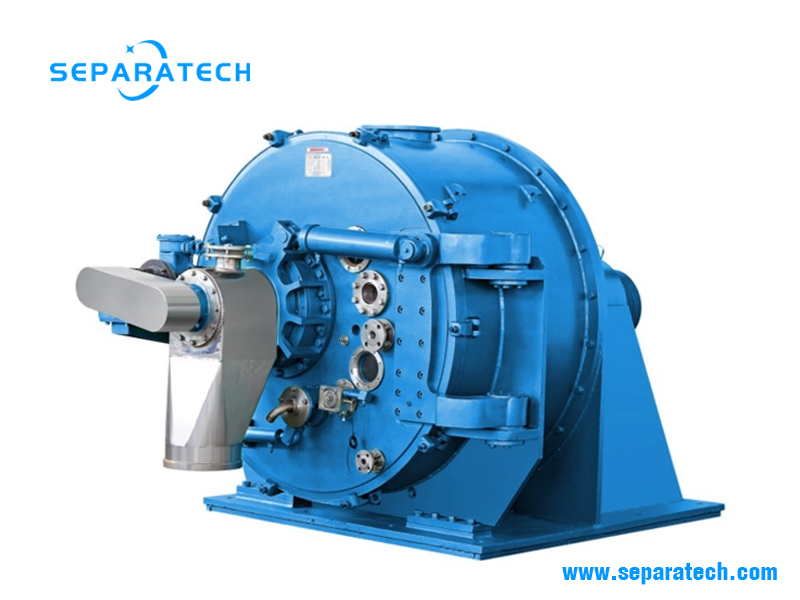

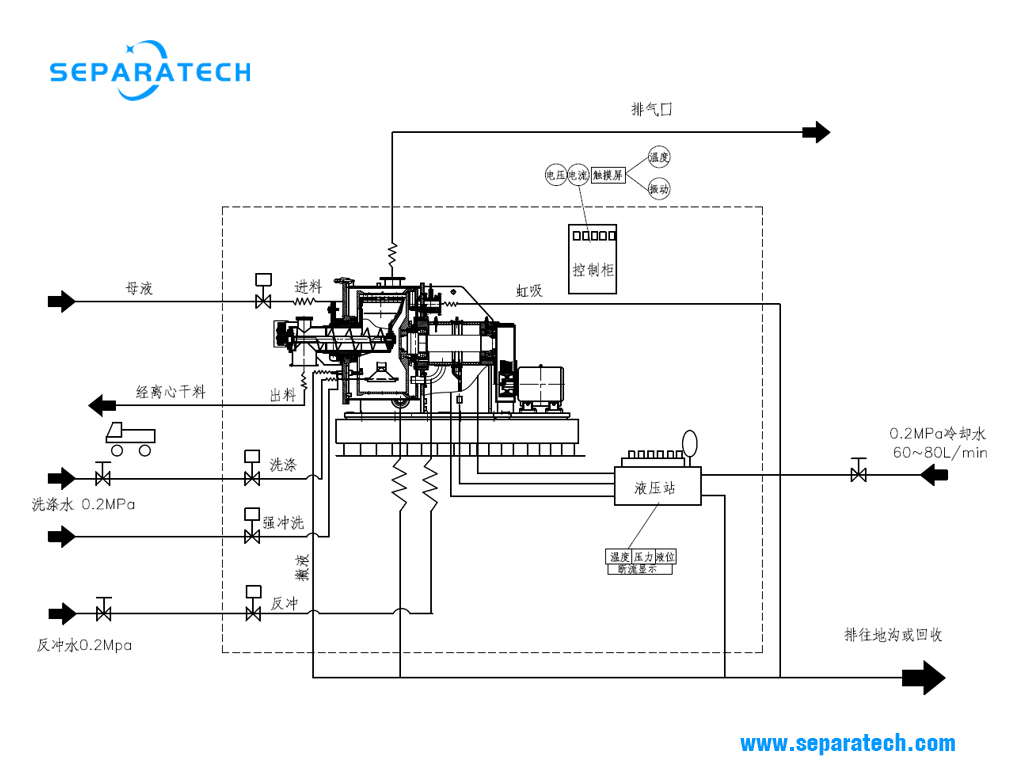

Peeler centrifuge diagram

Peeler centrifuge specifications

| Designation | Basket diameter (mm) | Basket height (mm) | Basket volume (L) | Speed (r/min) | Loading capacity (Kg) | Motor power (KW) | Weight (Kg) |

|---|---|---|---|---|---|---|---|

| PS800 | 800 | 450 | 100 | 1550 | 150 | 45 | 5000 |

| PS1250 | 1250 | 600 | 350 | 1200 | 450 | 90 | 11000 |

| PS1600 | 1600 | 1000 | 880 | 950 | 1000 | 132 | 17000 |

| PS1800 | 1800 | 1250 | 1390 | 800 | 1800 | 160 | 25000 |