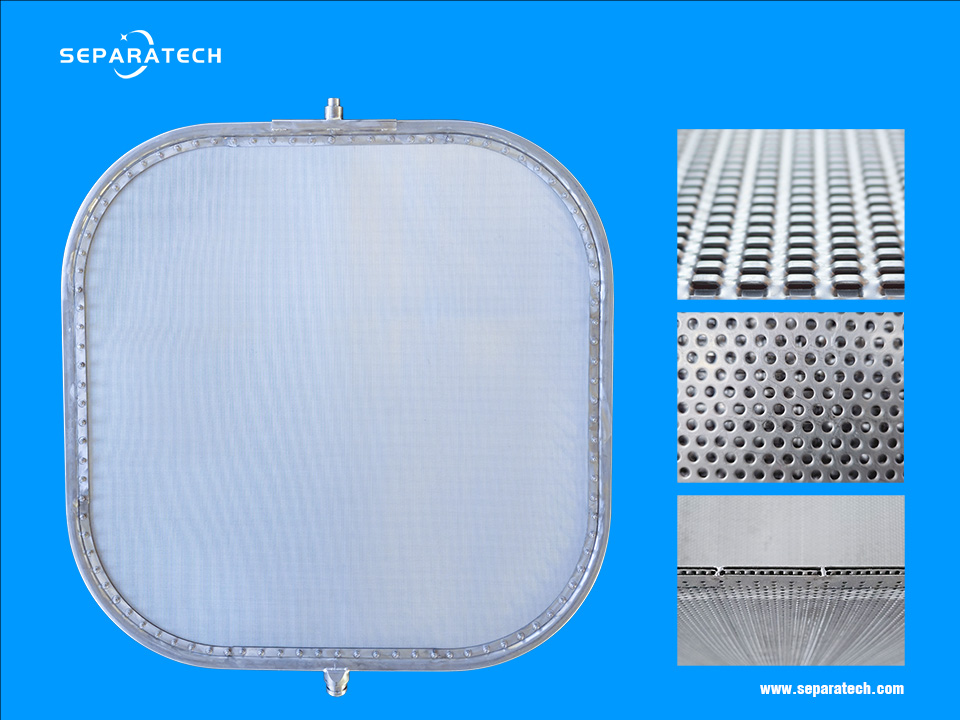

Filter Leaves are the heart of the filter system and therefore the most critical part of the Liquid Sulphur Filter. Good filtration performance begins with quality filter leaves. SEPARATECH offers various designs of Filter Leaves for all brands of pressure leaf filters. Standard Filter Leaves consist of several layers of mesh, the inner mesh coarser for a free flow of the filtrate and the support of the drainage and filter layer.

Molten sulphur filtration is a critical process in industries ranging from chemical manufacturing to fertilizer production. At the heart of this operation lies the pressure leaf filter, a highly efficient and reliable system designed to remove impurities from molten sulphur. Among its key components, the filter leaf plays a pivotal role, ensuring optimal filtration performance. This article delves into the importance of filter leaves in molten sulphur filtration and highlights why SEPARATECH is your trusted partner for custom-designed filter leaves.

The Role of Filter Leaves in Molten Sulphur Filtration

Filter leaves are the backbone of any pressure leaf filter. These robust, precisely engineered components are constructed from fine mesh layers supported by a rigid frame. Their primary purpose is to trap solid impurities while allowing the clean molten sulphur to pass through.

In molten sulphur filtration, the operational demands on filter leaves are particularly high due to the material’s high temperature and viscosity. To ensure consistent filtration, filter leaves must provide:

Durability:

Resistant to the corrosive nature of molten sulphur.

Precision:

Engineered to meet specific pore sizes for effective impurity retention.

Efficiency:

Minimized clogging and easy cleaning for prolonged operational life.

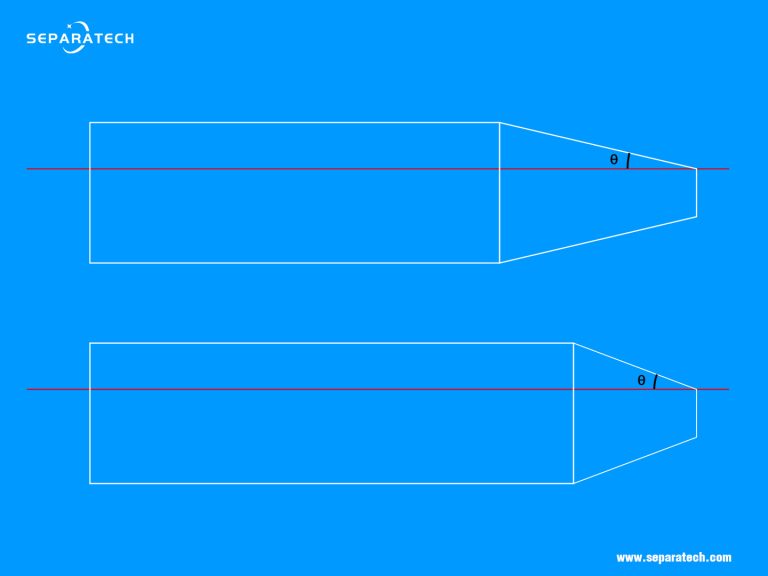

The Structure of Filter Leaves in Molten Sulphur Filtration

SEPARATECH offer two types, 5 layer and 3 layer Filter Leaves for liquid sulphur filtration.

We offer bolted construction so the Filter Leaves can be remeshed on-site. All filter leaves have a filtrate discharge outlet nozzle. This can be equipped with a single or dual “O”-ring construction for a leakage free sealing.

– Centre Screen: perforated metal sheet / 4 * 4 mesh

– Support Screen: perforated metal sheet / 8 * 8 mesh

– Filtration Screen: 24 * 110 Plain Dutch Weave

– Material: SS316L / SS904L

Why Choose SEPARATECH for Filter Leaves?

SEPARATECH stands out as a leading provider of custom-designed filter leaves tailored for all brands of pressure leaf filters. With extensive experience in filtration solutions, SEPARATECH’s filter leaves deliver unmatched performance for molten sulphur filtration. Here’s why:

Custom Design and Compatibility

SEPARATECH offers filter leaves that are compatible with all major pressure leaf filter brands. Every filter leaf is designed to match your specific filtration system and process requirements.

High-Quality Materials

To withstand the harsh conditions of molten sulphur filtration, SEPARATECH uses premium-grade stainless steel and advanced corrosion-resistant alloys. This ensures long-lasting performance and reduced maintenance costs.

Expert Engineering

Each filter leaf is meticulously crafted to provide optimal filtration efficiency. SEPARATECH’s engineering team incorporates multiple mesh layers, special perforated mesh, and designs that promote even flow distribution and prevent premature clogging.

Cost-Effective Solutions

SEPARATECH’s filter leaves offer excellent value by reducing downtime, extending filter life, and improving the overall efficiency of your molten sulphur filter system.

Invest in Performance and Reliability

When it comes to molten sulphur filtration, don’t compromise on quality. SEPARATECH’s custom-designed filter leaves are the smart choice for businesses looking to enhance their filtration systems. With SEPARATECH, you gain access to world-class expertise, premium products, and dedicated customer service.

Contact SEPARATECH today to learn more about how our filter leaves can revolutionize your molten sulphur filtration process. Let us help you achieve superior filtration performance tailored to your unique requirements.