Innovative edible oil deodorizer design for deodorization process in oil refining

Innovative edible oil deodorizer design from SEPARATECH, a firm that cooperated with specialized team in designing and manufacturing high-quality deodorization systems for various types of oils and fats. Ultra-high efficiency in deodorization process in oil refining.

Application purpose

The edible oil deodorizer design from SEPARATECH is special designed for removing the volatile compounds, flavors, hydroperoxides, and some contaminants in the oil, in a process that takes place at 180°C–240°C. It is a process correlated with the reduction of FFA in the oil. These unwanted substances negatively affect the odor, flavor, color and stability of the final product . Deodorization is a steam-distillation process that takes place under vacuum and high temperature conditions.

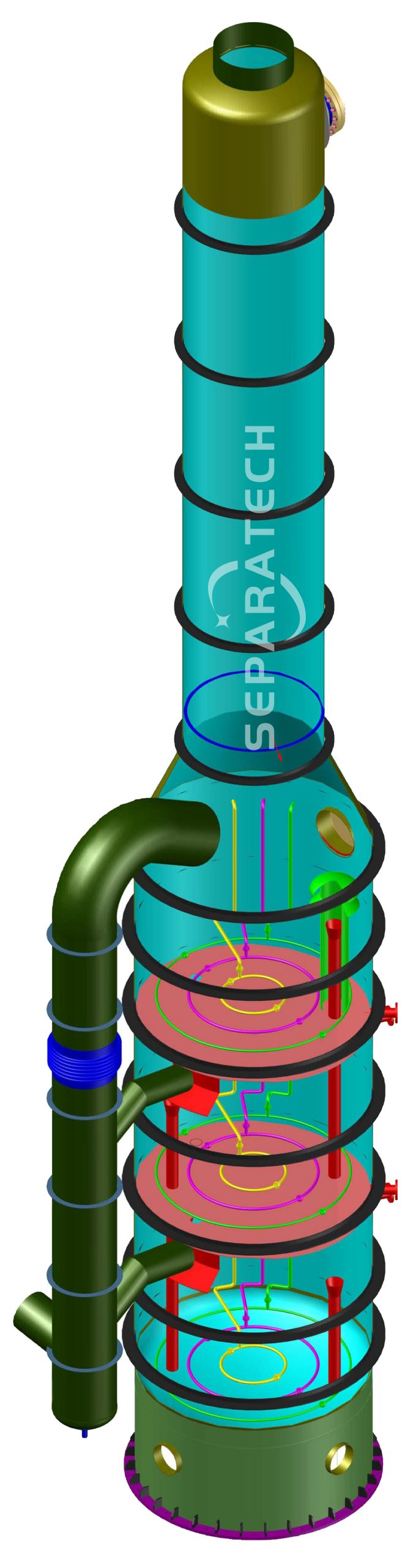

Main structure of edible oil deodorizer design

The main structure of the SEPARATECH edible oil deodorizer consists of a deaerator, an economizer, a final heater, a deodorization column and a condenser. The deaerator removes air from the oil under vacuum to prevent oxidation. The economizer regeneratively heats the oil by using the hot oil leaving the deodorization column. The final heater brings the oil to the exact temperature required for deodorization, normally using high-pressure steam. The deodorization column is where the actual stripping of free fatty acids and volatile components takes place. The column can have a stripping section and a retention section, depending on the type of oil and the desired quality . The condenser cools down and recovers the vapours leaving the column.

Working principle

The working principle of the edible oil deodorizer designed based on the difference in volatility between the oil and the unwanted substances. When steam is passed through the oil at high temperature and low pressure, the free fatty acids and volatile components are evaporated and carried away by the steam. The oil is then discharged from the bottom of the column as a refined product.

Features and advantages

– It uses less steam and operates at lower temperatures than conventional deodorizers, resulting in more gentle and effective treatment that greatly benefits the quality of the fats and oils .

– It is extremely versatile and can handle different types of oils, such as palm, soybean, rapeseed or other edible oils, with different processing requirements .

– It has a smart instrumentation and control system that makes it easy to operate and monitor .

– It has a patented thin-film technology that enhances the stripping and retention efficiency of the column .

– It reduces product loss and utility consumption by optimizing heat recovery and minimizing residence time .

– It improves GE removal to levels below 0.5 ppm and reduces TFA isomers formation .

The edible oil deodorizer designed from SEPARATECH is an excellent choice for anyone who wants to produce high-quality refined oils with minimal environmental impact and maximum profitability. For more information about this product, please contact us directly for more details.