Centrifugal mixer CM for edible oil refining

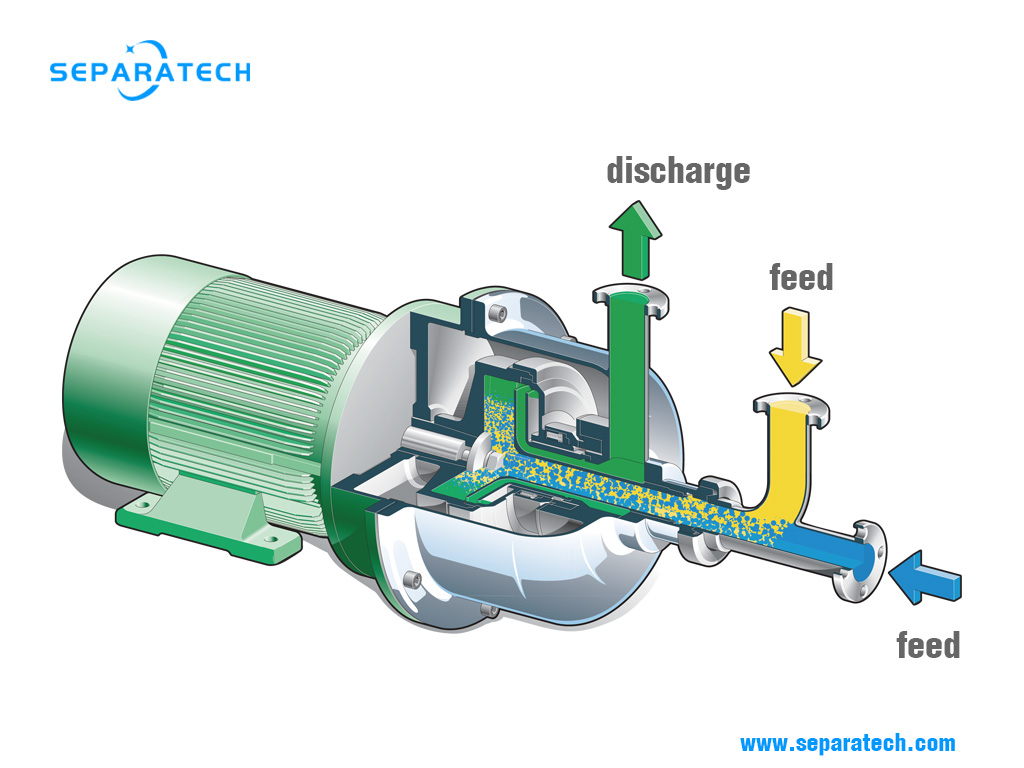

CM multipurpose centrifugal mixer is a special type of centrifugal mixer that is used to mix two or more liquids with different densities and viscosities in a continuous process. It is a high-speed, high-shear mixer that is used in the edible oil refining process. The CM centrifugal mixer has a removable hood and a centripetal pump for liquid discharge. The purpose of the CM centrifugal mixer is to achieve a homogeneous and stable mixture of the liquids, which can improve the quality and yield of the edible oil products. The function of the CM centrifugal mixer is to create a high shear force between the liquids by rotating them at a high speed in a cylindrical chamber. The shear force breaks up the droplets of the liquids and distributes them evenly throughout the mixture. The CM centrifugal mixer can handle a wide range of densities, viscosities, temperatures and flow rates, making it a versatile and efficient device for edible oil refining.

Application of centrifugal mixer

The CM centrifugal mixer is a versatile and effective tool for the edible oil refining process. It can be used to disperse a wide variety of materials, including alkali /lye, acid, water. The mixer is also capable of handling high viscosity oils, such as soybean oil and peanut oil.

Working principle

The CM centrifugal mixer from SEPARATECH works on the principle of centrifugal force. The mixer consists of a cylindrical housing with a rotating impeller at the center. The impeller is fitted with a number of vanes that create a high-shear vortex within the housing. The oil and liquid solution are fed into the housing at the top and are quickly drawn into the vortex. The high shear forces of the vortex break down the liquid solution and disperse them throughout the oil.

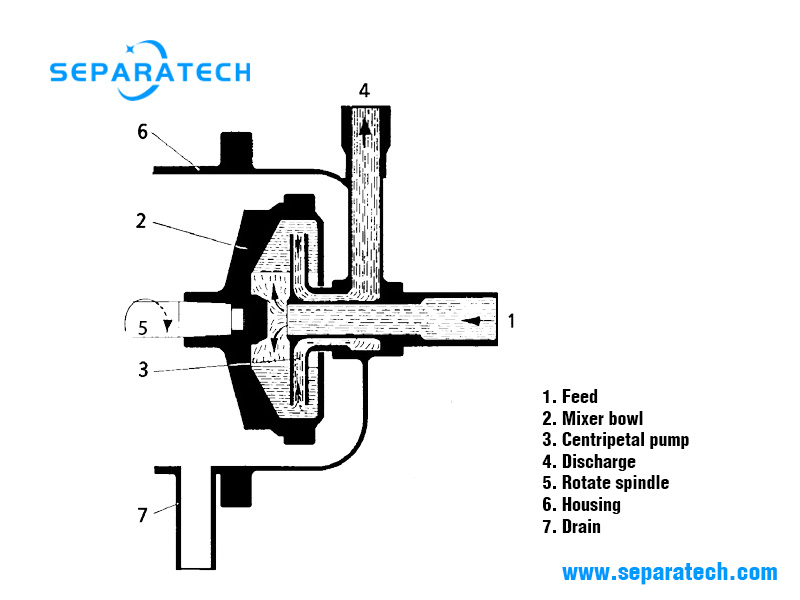

1. Feed

2. Mixer bowl

3. Centripetal pump

4. Discharge

5. Rotate spindle

6. Housing

7. Drain

Benefits

– Short mixing time and high process flexibility

– No lump formation or ‘fish eyes’

– High energy efficiency and low maintenance costs

– Easy cleaning and CIP-compatibility

– Rapid mixing of liquid solution into oil

– Improved quality and consistency of the finished product

– Increased production capacity

– Reduced energy consumption

– Safe and reliable operation

Materials

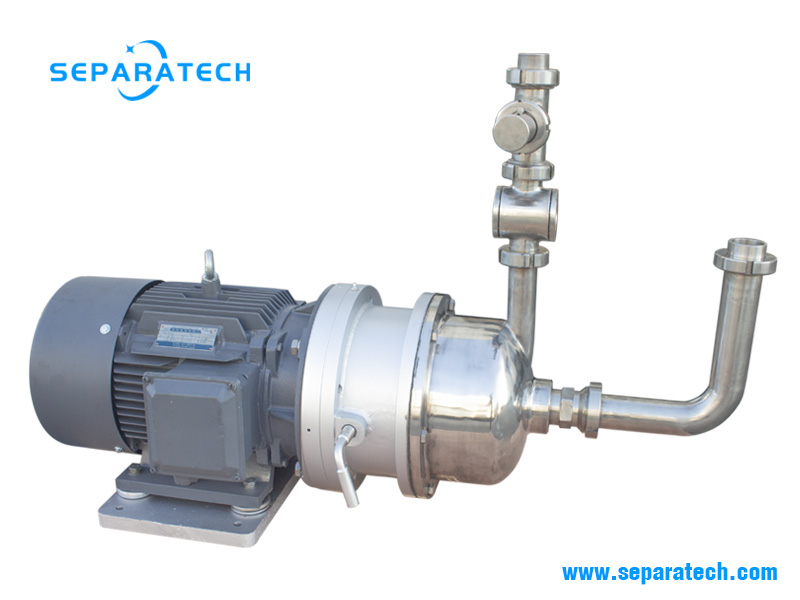

All parts coming into contact with the product (hood, bowl, centripetal pump, feed and discharge connections) are made of stainless steel.

Opening the centrifugal mixer

When a centrifugal mixer has to be opened, the following points must be observed.

• Do not loosen any part before the machine has come to a standstill.

• The safety aspects below must be assured:

– The centrifugal mixer is at standstill.

– The nitrogen supply must be shut off.

– The electrical safety must be ensured.

Caution: Opening the machine can release large quantities of nitrogen or residues of combustible gases or product residues.

Technical specifications

| Designation | Capacity (T/d) | Power (Kw) |

|---|---|---|

| CM40 | 100 | 3.0 |

| CM80 | 200 | 5.5 |

| CM100 | 500 | 11.0 |

The CM centrifugal mixer is a safe and reliable piece of equipment. It is designed to operate at high speeds without overheating or damaging the oil. The mixer is also equipped with a number of safety features, such as a pressure relief valve and a temperature sensor.

The CM centrifugal mixer is a valuable asset to any edible oil refinery. It is a high-performance mixer that can help to improve the quality and consistency of the finished product.

If you are looking for a high-performance mixer for your edible oil refinery, the CM centrifugal mixer from SEPARATECH is a great option.