Self-Cleaning Disc Separator

Self-Cleaning Disc Separator with self-cleaning bowl, is able to periodically discharge the separated solids at full speed. it is mainly used for liquid/liquid/solid continuous separation.

Self-Cleaning Disk Separator is also equipped with a stack of conical disks to create a large equivalent clarification area within a relatively small bowl volume. Self-Cleaning Disk Separator. For solids discharge, several solids discharge ports are spaced evenly around the bowl periphery. These ports are opened and closed by means of a movable sliding piston located in the bowl bottom. The opening mechanism is actuated hydraulically. Water is normally used as a control medium; in special cases, low-viscous organic fluids can also be used.

This opening mechanism enables both partial ejections and total ejections. Total ejections involve discharging the entire contents of the bowl with closed feed valve. In the case of a partial ejection, by contrast, only part of the bowl contents is ejected with open feed valve.

As with solids retaining separator, the Self-Cleaning Disk Separator is likewise available as versions for clarification and separation, even concentration.

Working principle of Self-Cleaning Disc Separator

Self-cleaning separator is for applications that require continuous processing.

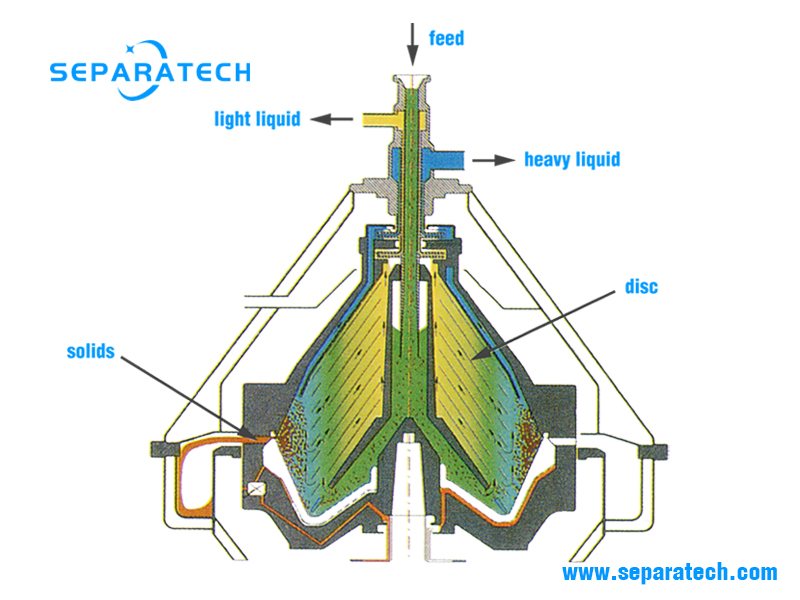

The suspension to be separated is fed into the self-cleaning separator bowl from the top through a feeding pipe and enters the disc stack. Separation takes place in the disc stack; the solids are separated out in the solids holding space.

The heavy liquid phase and solids phase are forced towards the periphery of the bowl, while the light phase flows towards the centre of the bowl, from where it is pumped out under pressure for further processing.

The heavy liquid phase is led over a top disc into a chamber where a centripetal pumps it out of the self-cleaning disc separator.

Solids collected in the solids holding space and is discharged intermittently and automatically. The solids holding space is of double conical form and incorporates ejection ports which can be opened and closed by hydraulically lowering and raising the sliding piston. The discharge is achieved by a hydraulic system, which at preset suitable intervals forces the sliding bowl bottom to drop down, thus opening the solids discharge ports at the bowl periphery. The solids is collected in the lower frame hood, and leaves the self-cleaning separator via a hydra cyclone.

During production the accumulated solids can be ejected instantaneously at preset intervals by lowering the sliding piston. At the end of the production phase the self-cleaning separator is automatically cleaned in place. Operation can be fully automated by installing suitable control units.

Conventional material data of Self-Cleaning Disc Separator

All parts coming in contact with the product are made of austenitic Cr-Ni-Mo steels or, in the case of highly stressed bowl parts, of martensitic Cr-Ni-Mo steels or duplex alloys.

Standard equipment of Self-Cleaning Disc Separator

Self-Cleaning Disk Separator consists of a frame with a base that contains a horizontal drive shaft, worm gear, lubricating oil bath, vertical bowl spindle, inlet and outlet devices, revolution counter, vibration-isolating base plate, and AC motor. The bowl is fixed on top of the spindle, inside the space formed by the upper part of the frame, the solids collecting cover, and the frame hood. The hood carries the liquid discharge system.

All parts in contact with the process liquid are made of stainless steel.

Cleaning-in-place (CIP) of Self-Cleaning Disc Separator

Once the centrifugation process has been completed, the Self-Cleaning Disk Separator can be cleaned-in-place. The cleaning solution is circulated through the centrifuge and the connected system. Total ejections are initiated during CIP manually or automatically on the control unit via an external CIP control.

Control system of Self-Cleaning Disc Separator

The following systems are available for controlling the automatic bowl ejections:

– Time-dependent control.

Recommended for use with products in which the solids loading remains constant.

– Photoelectric control using turbidity measurement.

This automatic ejection system can be used as an alternative. If a preset turbidity level is exceeded, a signal is sent to the control unit which triggers the solids ejection process. This control system is recommended for use with translucent products with fluctuating solids loading or if the throughput varies. This monitoring system can be installed on every standard Self-Cleaning Disc Separator.