Industrial Cream Separator

Milk cream separation

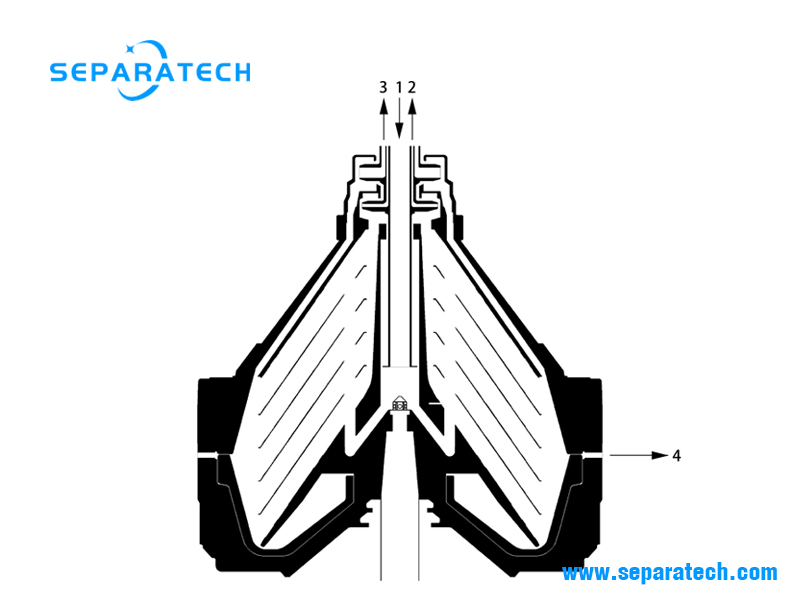

The milk to be treated flows into the industrial cream separator through feed pipe (1) and into the distributor where it undergoes acceleration until it reaches the bowl rotating speed. The distributor conveys the milk to the disc stack where the separation between light and heavy phase takes place. Light phase (cream) flows to the centre of the bowl and heavy phase (skimmed milk) flows to the bowl outer diameter. Both phases rise in the disks stack and reach the two upper chambers of the bowl. Here two fixed centripetal pumps convey cream (2) and skimmed milk (3) under pressure and foam-free out of the industrial cream separator.

Milk Clarification

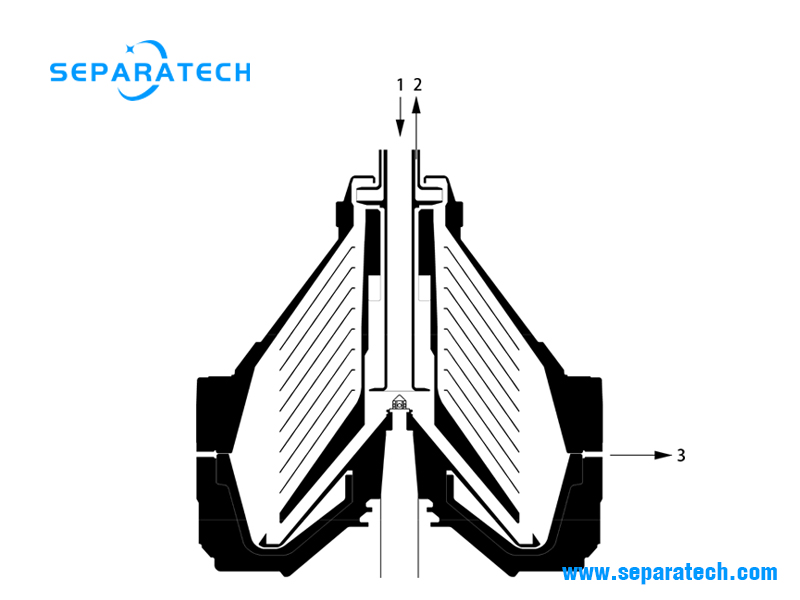

The milk to be clarified flows into the industrial cream separator through feed pipe (1) and into the distributor where it undergoes acceleration until it reaches the bowl rotating speed. The distributor conveys the product to the disks stack where the clarification takes place. The clarified liquid (cleaned milk) rises in the disks stack and reaches the upper chamber of the bowl. Here a fixed centripetal pump conveys cleaned milk (2) under pressure and foam-free out of the industrial cream separator.

Solids discharge

The separated solids are collected in the peripheral part of the bowl and are periodically discharged through the discharge holes to maintain the required separation and/or clarification efficiency. The discharged solids are collected into an outer annular chamber and drained away by gravity via the centrifuge cyclone of industrial cream separator.

The pressure produced by water in the chamber keeps the hydraulic operated sliding piston in closed position. By feeding with operating water, the opening piston valve lets the water in close chamber to flow away; the product pressure pushes down the hydraulic operated sliding piston and the solids are immediately ejected through the solids discharge ports. By stopping the operating water feed and filling the closing operating water into the close chamber, the hydraulic operated sliding piston goes back to the closed position. The partial ejection / discharge does not require the stopping of the process; actually, it takes place at the rated revolving speed and without interrupting the product flow. The discharge of total type, with the complete emptying of the bowl, requires a prolonged bowl opening and requires to stop the feeding of the product into the industrial cream separator for a time sufficient to the pickup of the nominal speed.

Automatic control

The periodical solids discharge is carried out automatically by means of a PLC (Programmable Logic Controller) which controls the opening and closing operating water solenoid valves of industrial cream separator. Generally various automatic, independent working cycles may be selected to perform partial and/or total ejection during separation and cleaning in place. By setting the parameters in PLC it is possible to adjust the discharged volume, the frequency and in some cases the combination between partial and total discharges.

The PLC can also realize the following functions: automatic bowl closing during the starting phase; stopping of the feeding, during total discharges; rinsing of all internal surfaces, before and after the discharge; manual control of partial and total discharges; bowl overflow (during CIP), as well as CIP procedure.

Warm milk separation with industrial cream separator

Milk separation during pasteurisation is the most common application for the industrial cream separator in dairies. Raw milk of known fat content, free from air, should be fed to the industrial milk cream separator at relatively constant temperature and capacity. The globular milk fat is separated from the skim milk, and this separation normally takes place between 45°C and 65°C. This temperature assures a good skimming efficiency and a low viscosity of the outlet cream. The skimming efficiency is influenced by milk temperature, seasonal variation, milk quality, mechanical treatment and air suction upstream the industrial cream separator. Standardized cream and skimmed milk are the products leaving the industrial cream separator. Sediment discharged from the industrial cream separator centrifuge during separation may contain bacteria, leucocyte, hair, sand and similar. If the hot milk industrial cream separator is the first centrifugal clarification step in the dairy, the discharged sediment is not possible to recycle. Skimming efficiency is expressed as residual fat content in the skimmed milk. At rated capacity, industrial cream separator generally give a residual fat content lower than:

• 0,03% measured by GERBER method

• 0,05% measured by RÖSE-GOTTLIEB method

Milk clarification with industrial cream separator

In many cases milk must be clarified at first receiving by the dairy, to remove impurities from milk.

If process conditions are favorable, it is also possible to obtain an efficient reduction in the amount of leucocytes and bacteria. The milk clarifier can operate with cold or warm milk; however, a higher temperature increases the clarification efficiency. Disc centrifuges for milk separation (skimming) also perform a clarification but their efficiency is low in comparison to these milk clarifiers.

Raw milk, free from air, should be fed to the milk clarifier at relatively constant temperature and capacity. A change in operating conditions will influence the clarification efficiency.

Sediment discharged from the industrial cream separator centrifuge during clarification may contain bacteria, leucocyte, hair, sand and similar. Normally a milk clarifier is the first centrifugal operation in the dairy so the discharged sediment is not possible to use.

| Models | Skimming Capacity [L/h] | Standardization Capacity [L/h] | Motor [Kw] |

|---|---|---|---|

| DKS10 | 1000 | 1500 | 4 |

| DKS30 | 3000 | 4500 | 7.5 |

| DKS50 | 5000 | 7500 | 11 |

| DKS100 | 10000 | 15000 | 18.5 |

| DKS150 | 15000 | 22000 | 22 |

| Models | Capacity [L/h] | Motor [Kw] |

|---|---|---|

| DCS20 | 2000 | 4 |

| DCS60 | 6000 | 7.5 |

| DCS100 | 10000 | 15 |

| DCS200 | 20000 | 22 |

Milk bacteria removing with industrial cream separator

Milk bacterial separators are essentially used to improve milk quality both for drinking milk and cheese production. Due to their higher density micro-organisms may be separated from milk by means of centrifugation in a special industrial cream separator, a so called Bactofuge unit.

In the Bactofuge unit’s bowl (disc stack) the milk is separated into a light phase, with low concentration of micro-organisms, called “clean milk” and a heavy phase with spores and bacteria.

In the bowl, the clean milk is led all the way to the centre of the bowl, while the phase with spores and bacteria leaves the bowl over the top disc and/or are collected in the sediment space at the periphery of the bowl. The sediment space is emptied accurately and hydraulically at preset intervals. At the outlets, co-rotating pumps efficiently discharge the separated products from the centre.

The heavy phase with spores and bacteria may, depending on legality, after sterilization be recycled, used in other dairy products or disposed as regular centrifuge sediment. The general reduction of the amount of bacteria and the important abatement of the aerobic, anaerobic spores and listeria, allows to reduce pasteurisation temperatures, to avoid problems during cheese aging, and at the same time to improve the shelf-life, the organoleptic properties and the safety of the product.

Milk bacteria removing / clarification process can be performed in the two following ways:

• continuous extraction of bacteria concentrated milk flow that must be sterilized before reuse;

• recycle in the feed of the extracted concentrate and bacteria elimination by only partial discharges.

The first configuration certainly allows to limit at the minimum milk losses to the detriment however of a greater plant complication and cost and of a lower production quality.

On the contrary the second configuration shows the best compromise between installation costs, product quality and losses.

Cold milk separation with industrial cream separator

Cold milk separation permits interesting savings in energy and thermal equipments like heat exchanger and others. Cold raw milk of known fat content, free from air, should be fed to the special designed industrial cream separator, the cold milk separator at constant temperature and capacity. Cold milk separation conditions are not favorable, so skimming efficiency is lower than the one for warm milk and cream density cannot exceeds 40-45 % at 3-5 °C. Skimming efficiency increases by increasing temperature and/or reducing flow-rate. Viscosity and other cream characteristics at low temperature impose the use of special hermetic separator. Standardized cream and skimmed milk are the products leaving the separator. Sediment discharged from the industrial cream separator during separation may contain bacteria, leucocyte, hair, sand and similar. A cold separation is probably the first centrifugal clarification step in the dairy and therefore is the discharged sediment not possible to recycle. Any change in operating conditions is a potential risk for plugging of the bowl.

Cold milk separation at 3-10 °C takes place in some processes as:

• cheese making process when unpasteurized milk is used;

pre-standardization process with batch system (in this case is avoided a double heating treatment);

• high quality cream production.