Classifying Decanter Centrifuge

Classifying Decanter Centrifuge is mainly used for classifying of solids. Continuous separation of solids from suspensions with very high solids content of up to 60%, clarification of liquids, concentration of solids, classification of solids according to particle size.

Classification, the fractionation or separation of particles by size,could be considered as merely inefficient clarification. The cut, or desired classification, is adjusted by altering the classifying decanter centrifuge’s efficiency. This is most easily done by altering the feed rate or bowl speed of classifying decanter centrifuge. However, adjustment of pond depth or differential may. in certain circumstances, be used.

In some classification applications. the required cut point is very sharp and the rheology of both separated phases is such that they remain quite fluid. In this type of application, the classifying decanter centrifuge’s pond used would be relatively deep, and separation would be akin to a liquid-liquid separation, using a hydraulic balance under some form of baffle.

Very occasionally there will be found a classification application where it is required to separate two distinctly different particles. such as in the refining of minerals. In these cases, the two different substances to be separated may have markedly different densities. For classifying decanter centrifuge, it is particularly acceptable and quite advantageous when the denser material comprises the larger-sized particles. However, if this is not so. one must consider a combination of density and particle size for the cut point of each of the two substances, in relation to Stokes’ law. One could visualize the situation of a large, low-density particle settling faster than a high-density, small particle. Thus for such a process to be feasible.

Each of the two solid constituents will have their own size distribution from which a cut point size can be chosen to give the desired purity of product and yield by classifying decanter centrifuge.

Working principle of classifying decanter centrifuge

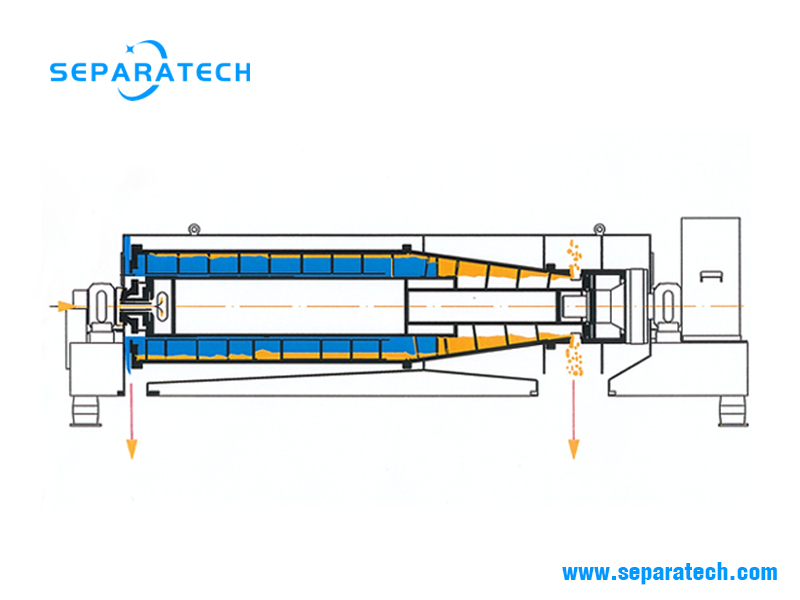

The solid-wall bowl has a cylindrical section for good separation and clarification of the liquid or classification of the solids and a conical section for dewatering the solids or concentration of the precipitated coarse particles.

The product is fed info the decanter through the feed and is conveyed to the separating or classifying chamber through the distributor. The liquid level of classifying decanter centrifuge can be adjusted by regulating plates. The coarse solid particles are forced to the wall of the bowl by the centrifugal force. The scroll conveys the precipitated solids particles to the solids discharge. The clarified liquid or the classified fine particles are discharged from the separating chamber via replaceable regulating plate.

Features of classifying decanter centrifuge

– High product yield of the processed raw materials or preliminary products

– Optimized bowl design for large clarification area and therefore highest performance

– Dynamic stability of the frame design for a long service life and high safety

– Intelligent drive systems for simple differential speed adjustment available achieving optimum dry-substance values

– Overload protection and protected bearings ensure permanent and reliable operation

– Depending on the area of application, the scroll is faced with hard-metal for wear protection

– Corrosion protection for all components which come into contact with product by the use of stainless-steel materials

– Rotational hard-metal wear bushes in the area of the solids discharge double the service life of the bushes

– Ease of access to all relevant components reduces maintenance time

– Available with gravity or pressure discharge of the clarified liquid phase

Applications of classifying decanter centrifuge

– Chemical industry

– Mineral processing

– Starch technology