Decanter Centrifuge Gearbox

The decanter centrifuge gearbox is a major component of the rotating assembly, which creates the differential speed between the bowl and the screw conveyor.

There are two main types of decanter centrifuge gearbox. One is the planetary (epicyclic) gearbox, the other one is the cycloidal (cyclo) gearbox. However there are a number of decanters which have eliminated the gearbox by using a hydraulic system.

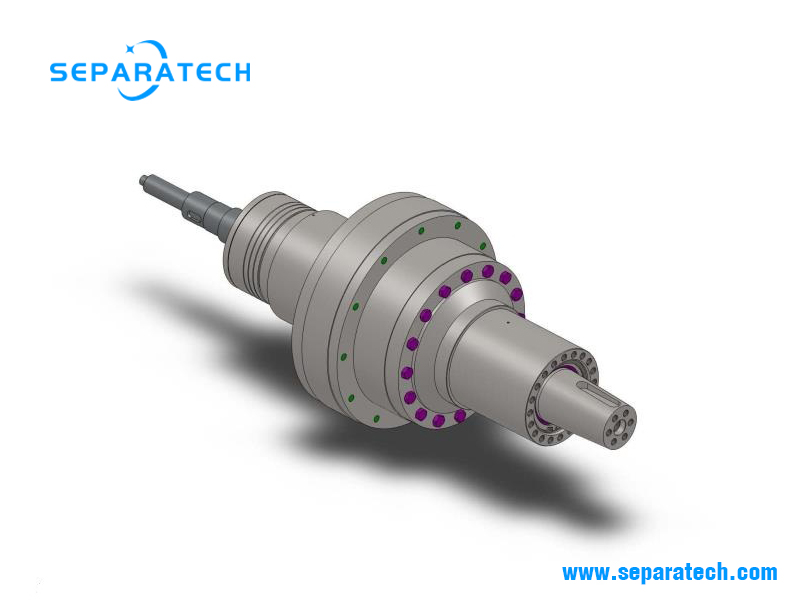

The planetary gearbox system consists of a pinion shaft and gear, which engages three planetary gears (mounted on carrier plates) which in turn engage a ring gear fixed to the gearbox casing. For the decanter centrifuge the epicyclic gearbox involves two stages. although recently three stages have been in use. The carrier plate of the first stage holds a second pinion shaft carrying the sun gear for the second stage. The ratio of the decanter centrifuge gearbox is the product of the ratios for each stage. The maximum practical ratio for any stage is just over 1 3. giving a maximum ratio for a two-stage planetary gearbox of 170 to 180. Three stage epicyclic gearboxes with ratios over 500 have been used on decanters.

If the central pinion shaft is held stationary. the differential speed between conveyor and bowl will be the bowl speed divided by the gearbox ratio. If the pinion shaft is allowed to rotate at some speed below the bowl speed, then the differential between bowl and conveyor will be the difference between bowl speed and pinion speed, divided by decanter centrifuge gearbox ratio. If the pinion speed is controlled by using a brake, or a variable speed motor. differential speed may be varied from close to maximum. when the brake is at its slowest speed, to nearly zero, when the brake is almost at bowl speed. Reducing the pinion speed below zero, i.e. by reversing, enables higher differential speeds to be obtained. Using an epicyclic gearbox causes the conveyor to rotate slower than the bowl. whereas it is normally faster when using a cycloidal decanter centrifuge gearbox. Generally the conveyor flight helix is “left handed” with an planetary decanter centrifuge gearbox and right handed with a cycloidal gearbox.

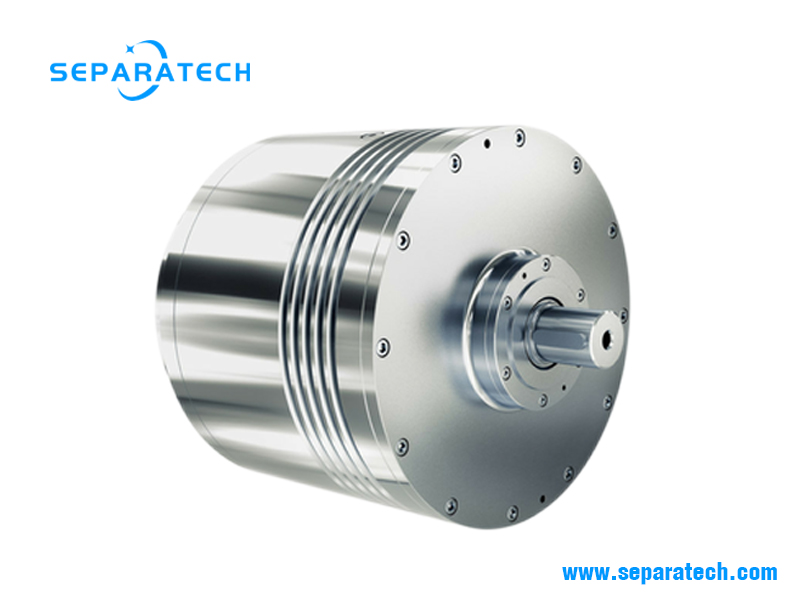

Two stage planetary gearbox parameters

| Designation | Transmission ratio | Rated torque (Nm) | Maximum speed (r/min) | Suitable bowl ID (mm) | Weight (Kg) |

|---|---|---|---|---|---|

| P2C2 | 95 | 1500 | 6000 | ≤300 | 45 |

| P2C3 | 57,90 | 4000 | 5000 | ≤400 | 70 |

| P2C4 | 57,90 | 6000 | 4000 | ≤500 | 90 |

| P2C5 | 32,47,59,90,105 | 7000~12000 | 3500 | ≤650 | 170 |

| P2C6 | 30,55,90 | 15000~20000 | 3000 | ≤700 | 250 |

| P2C7 | 38,50 | 25000 | 2500 | ≤800 | 280 |

| P2C8 | 40,47 | 35000~40000 | 2200 | ≤900 | 400 |

| P2C9 | 42,64 | 60000 | 2000 | 700 | |

| P2C10 | 41 | 90000 | 1800 | 950 |