A decanter centrifuge is a device that uses high-speed rotation to separate solid and liquid phases of different densities. Decanter centrifuges are widely used in various industries, such as wastewater treatment, food processing, oil and gas extraction, etc.

There are two main types of decanter centrifuge bowl design: countercurrent and co-current. In this post, I will explain the differences, characteristics, advantages and disadvantages of each type, and how they affect the performance and efficiency of the separation process.

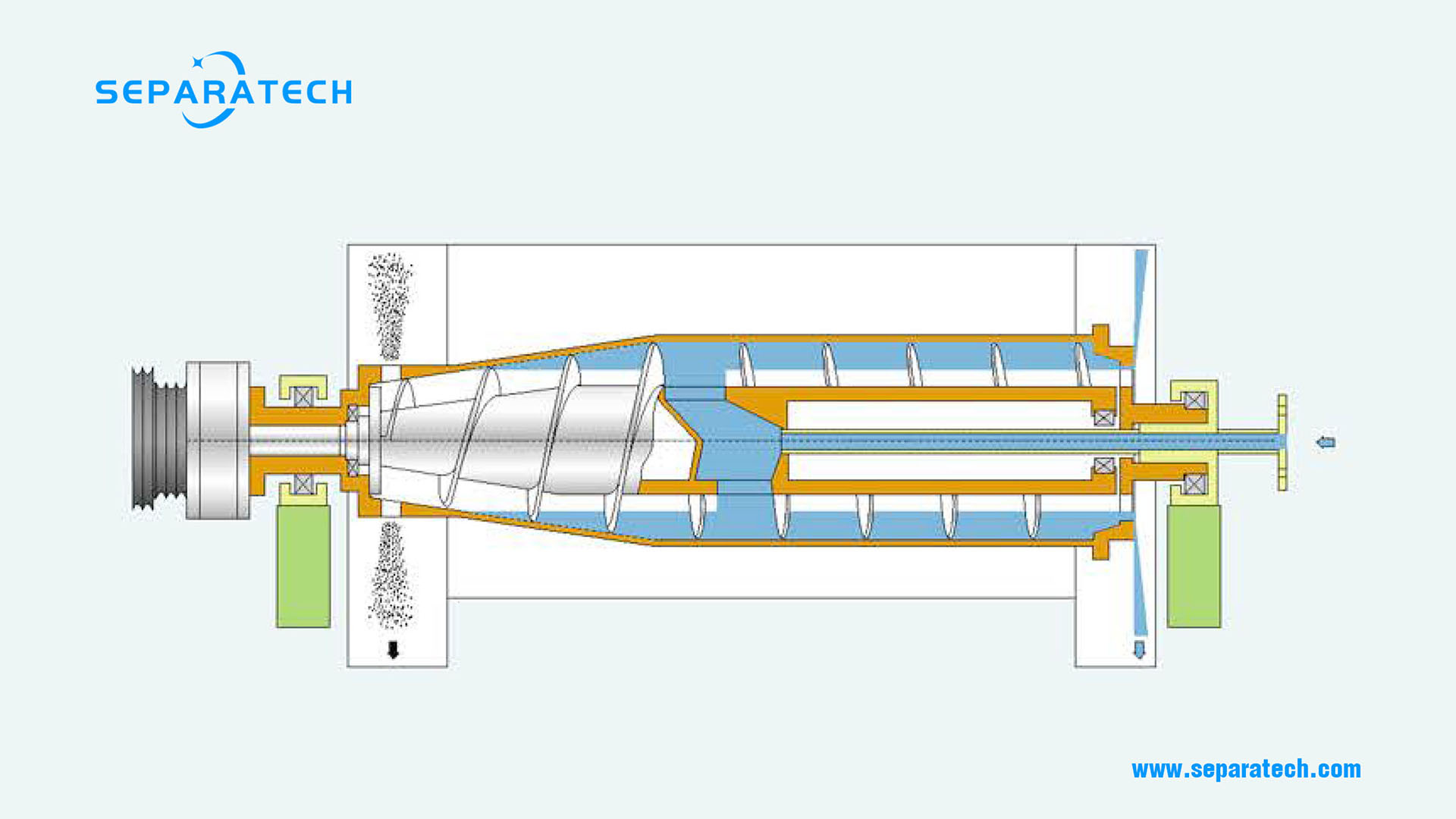

Countercurrent decanter centrifuge

A countercurrent decanter centrifuge has a feed inlet at the cylindrical end of the bowl, and a solids discharge at the conical end. The liquid phase exits from the opposite end of the feed inlet, over adjustable weir plates. The scroll rotates at a lower speed than the bowl, and conveys the solid particles towards the solids discharge.

The main advantage of countercurrent design is that it allows for a longer retention time of the solids in the bowl, which results in higher cake dryness and lower moisture content. This is especially beneficial for high solids and high hydraulic loading applications, where the goal is to maximize the recovery of dry solids and minimize the volume of liquid waste.

The main disadvantage of countercurrent design is that it requires a higher differential speed between the bowl and the scroll, which increases the power consumption and wear and tear of the machine. Moreover, countercurrent design may not be suitable for applications where the difference in density between solids and liquid is low, or where the solids have a complex shape or size distribution.

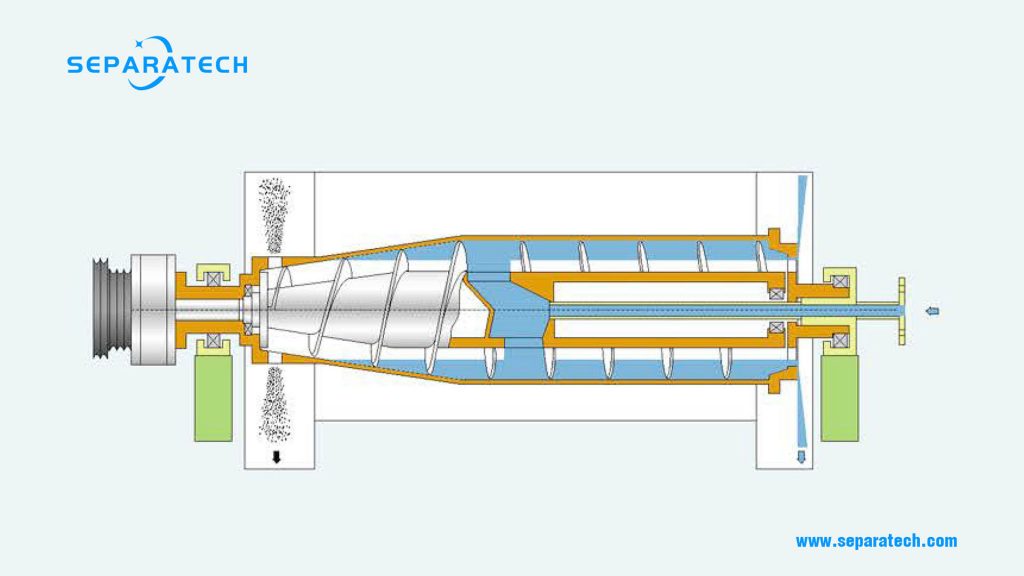

Co-current decanter centrifuge

A co-current decanter centrifuge has a feed inlet at the conical end of the bowl, and a solids discharge at the same end. The liquid phase exits from the cylindrical end of the bowl, over fixed weir plates. The scroll rotates at a higher speed than the bowl, and conveys the solid particles away from the solids discharge.

The main advantage of co-current design is that it allows for a lower differential speed between the bowl and the scroll, which reduces the power consumption and wear and tear of the machine. Moreover, co-current design can handle more complex applications, where the difference in density between solids and liquid is low, or where the solids have a complex shape or size distribution.

The main disadvantage of co-current design is that it allows for a shorter retention time of the solids in the bowl, which results in lower cake dryness and higher moisture content. This is especially problematic for applications where the goal is to minimize the recovery of dry solids and maximize the volume of liquid waste.

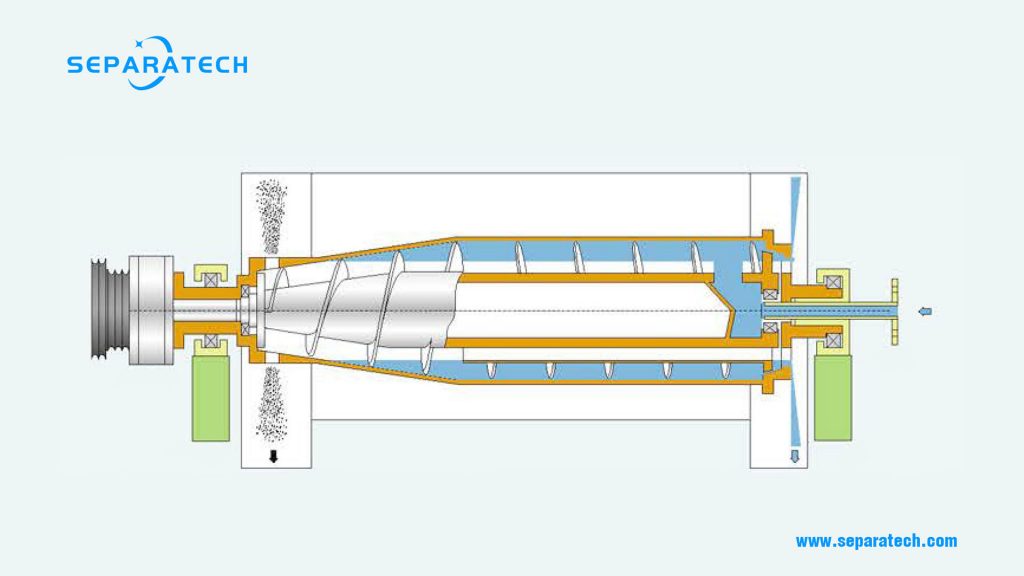

In conclusion, countercurrent decanter centrifuge and co-current decanter centrifuge have different advantages and disadvantages depending on the application and requirements. Countercurrent design is more suitable for high solids and high hydraulic loading applications, where higher cake dryness is desired. Co-current design is more suitable for low density difference and complex shape or size distribution applications, where lower differential speed is preferred.