Based on decades of experience in the design, manufacture, commissioning, and maintenance of decanter centrifuges, we have joined hands with relevant material research institutions and enterprises to provide original equipment manufacturers (OEMs) and rebuilders of decanter centrifuges with good wear resistance, high performance long life, reliability, affordable wear resistant components, including decanter centrifuge tile, discharge port liner, and other wear parts.

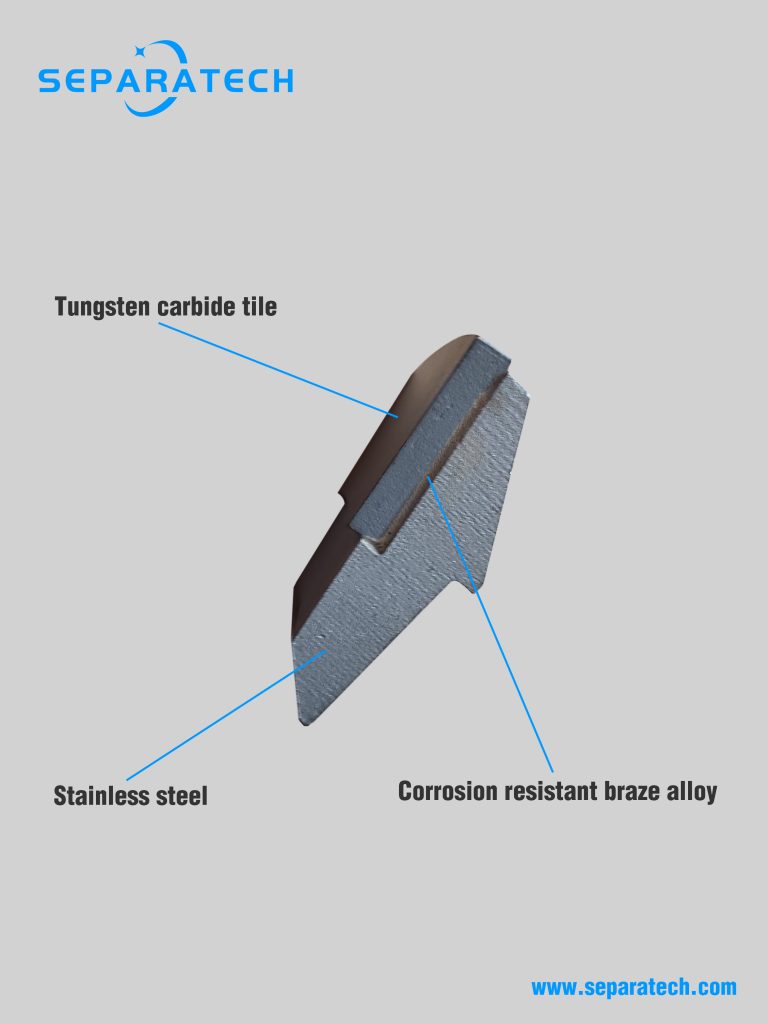

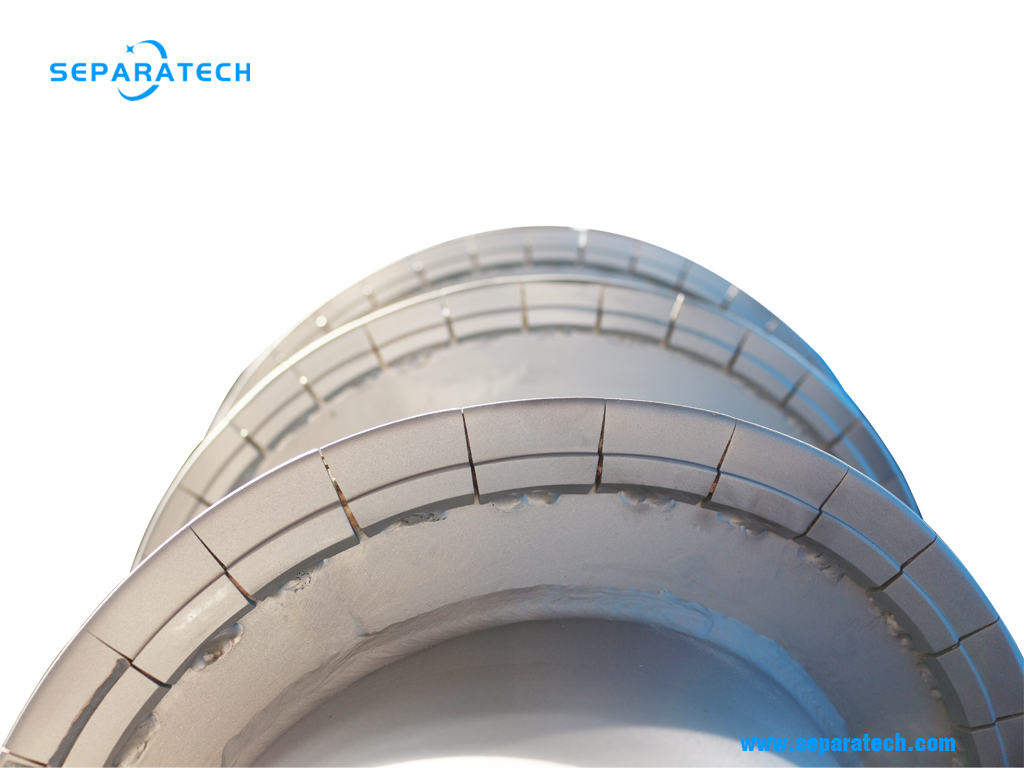

The decanter centrifuge tile is made of wear-resistant materials, such as tungsten carbide, ceramic, or hard metal alloys. The tile is attached to the bowl by welding, brazing, or mechanical fastening. The tile has a specific shape and size that matches the geometry and design of the bowl.

The decanter centrifuge tile is an essential part of the decanter centrifuge that ensures its performance, durability, and reliability. The tile requires regular maintenance and replacement to prevent wear and tear and to optimize the separation results.

Decanter centrifuge tiles functions

A decanter centrifuge is a device that separates solid and liquid materials using centrifugal force. The decanter centrifuge tile is a component of the decanter centrifuge that mounted on the scroll conveyor in the rotating bowl. The decanter centrifuge tile serves several functions, such as:

– Protecting the bowl from abrasion and corrosion caused by the solid particles in the slurry.

– Enhancing the separation efficiency by creating a smooth and uniform flow of the slurry along the bowl.

– Reducing the noise and vibration of the decanter centrifuge by absorbing some of the kinetic energy of the slurry.

Decanter centrifuge tile materials

Tungsten carbide tiles are one of the most common materials used for decanter centrifuge tile lining in decanter centrifuges. Tungsten carbide tiles have several advantages over other materials, such as ceramics, metals, or polymers. Some of these advantages are:

– Tungsten carbide tiles have a high hardness (68-93 HRa) and a high shear strength (20,000-50,000 psi), which make them resistant to impact, erosion, and abrasion.

– Tungsten carbide tiles have a low coefficient of friction (0.1-0.2), which reduces power consumption and heat generation in decanter centrifuges.

– Tungsten carbide tiles have a high thermal conductivity (60-120 W/mK) and a low thermal expansion (4.5-6.3 x 10^-6 K^-1), which enable them to withstand thermal shocks and temperature fluctuations.

– Tungsten carbide tiles have a high chemical resistance, which makes them suitable for handling acidic, alkaline, or corrosive fluids.

Tungsten carbide tiles can be applied to decanter centrifuges by two methods: brazing or vacuum bonding. Brazing involves heating the tiles and the metal parts to a high temperature (800-1000°C) and using a filler metal to join them together. Vacuum bonding involves applying a thin layer of adhesive to the tiles and the metal parts and curing them under vacuum pressure (10^-5 Torr) at a low temperature (150-200°C). Both methods require strict quality control to ensure permanent placement and consistency.

Tungsten carbide tiles can extend the life of decanter centrifuges by up to 50 times compared to mild steel and by up to 10 times compared to ceramics. Tungsten carbide tiles can also improve the performance and efficiency of decanter centrifuges by reducing maintenance costs, downtime, energy consumption, and environmental impact. Tungsten carbide tiles are therefore an ideal choice for decanter centrifuge tile lining in various applications.