Alkyd resin is a type of synthetic resin that is widely used in paints, varnishes and coatings. Alkyd resin is derived from the reaction of polyols, such as glycerol or pentaerythritol, with dicarboxylic acids or anhydrides, such as phthalic anhydride, and modified with unsaturated fatty acids, such as linseed oil or soybean oil.

The production of alkyd resin involves two main processes: the fatty acid process and the alcoholysis or monoglyceride process. The fatty acid process produces higher-quality and higher-performance alkyds by controlling the composition of the resin more precisely. The alcoholysis process produces more economical alkyds by transesterifying raw vegetable oil with additional polyol.

In both processes, the alkyd resin is formed by polycondensation of the reactants in a reactor vessel. The reaction is usually carried out at elevated temperatures and pressures, and requires a catalyst, such as cobalt or manganese salts. The reaction time and conditions depend on the desired properties of the final product, such as viscosity, molecular weight, color and drying characteristics.

After the reaction is completed, the alkyd resin is transferred to a storage tank, where it is cooled and stabilized. The alkyd resin may contain impurities, such as unreacted raw materials, catalyst residues, water and air bubbles. These impurities can affect the quality and performance of the alkyd resin, such as its clarity, gloss, film formation and durability. Therefore, it is necessary to filter the alkyd resin before using it for coating applications.

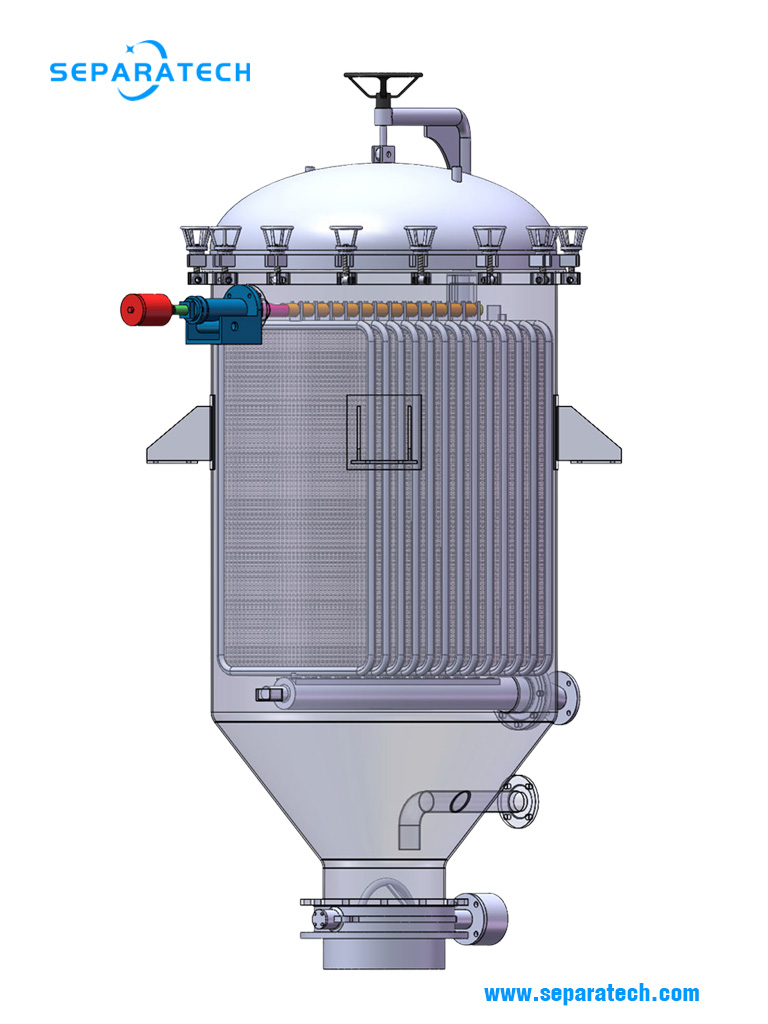

One of the most effective and efficient methods for filtering alkyd resin is using a pressure leaf filter. A pressure leaf filter consists of a cylindrical vessel that contains a number of filter elements, also called leaves. The leaves are made of stainless steel mesh that is supported by a perforated metal frame. The leaves are arranged vertically inside the vessel and connected to a manifold at the top. The alkyd resin enters the vessel from the bottom and flows through the spaces between the leaves. The impurities are trapped by the mesh and form a filter cake on the surface of the leaves. The filtered alkyd resin exits the vessel from the top through the manifold.

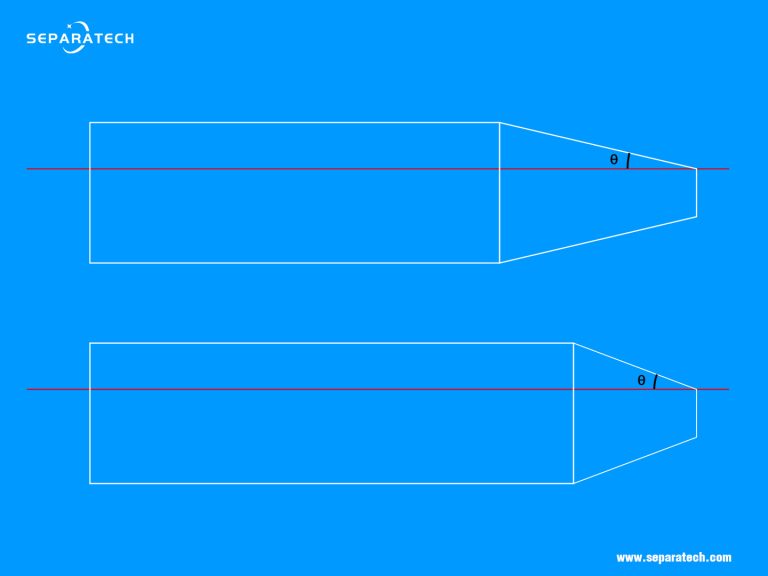

There are two types of pressure leaf filters: vertical and horizontal. A vertical pressure leaf filter has a vertical vessel with a conical bottom that facilitates the discharge of the filter cake. A horizontal pressure leaf filter has a horizontal vessel with a cylindrical shape that allows for a larger filtration area. Both types of pressure leaf filters have advantages and disadvantages depending on the specific application and operating conditions.

Benefits of using pressure leaf filters for alkyd resin filtration :

– High filtration efficiency: Pressure leaf filters can remove up to 99% of the impurities from the alkyd resin, resulting in a clear and high-quality product.

– Low operating cost: Pressure leaf filters have low maintenance and energy requirements, as they operate at low pressures and temperatures, and have no moving parts.

– Easy operation: Pressure leaf filters have simple and automated operation, as they can be controlled by valves and sensors that regulate the flow rate, pressure and temperature of the alkyd resin.

– High capacity: Pressure leaf filters have high filtration capacity, as they can handle large volumes of alkyd resin in a single cycle.

– Long service life: Pressure leaf filters have long service life, as they are made of durable materials that resist corrosion and wear.

SEPARATECH is a leading manufacturer and supplier of pressure leaf filters for various industries, including alkyd resin production. SEPARATECH offers both vertical and horizontal pressure leaf filters that are designed to meet the specific needs and requirements of each customer. SEPARATECH’s pressure leaf filters are made of high-quality materials and components that ensure reliable performance and durability. SEPARATECH’s pressure leaf filters are also equipped with advanced features and accessories that enhance their functionality and efficiency.

SEPARATECH’s pressure leaf filters have been widely used for alkyd resin filtration in many countries around the world. SEPARATECH’s customers have reported positive feedback and satisfaction with their products and services. SEPARATECH’s pressure leaf filters have helped them improve their product quality, reduce their operating costs, increase their productivity and profitability.

If you are looking for a reliable and efficient solution for your alkyd resin filtration needs, contact SEPARATECH today to get more information about their pressure leaf filters.