Coconut water, the clear liquid extracted from young coconuts, has gained immense popularity as a refreshing and nutritious beverage. Rich in electrolytes and low in calories, it has earned its place on supermarket shelves and health food stores worldwide. However, the journey from coconut tree to bottled drink involves a crucial step: coconut water processing. Among the most effective methods employed in this process is the use of disc separators.

Why is coconut water so healthy?

Coconut water is considered healthy due to its high electrolyte content, particularly potassium, which helps with hydration and maintaining fluid balance. It also contains vitamins, minerals, and antioxidants that can aid digestion, support heart health, and boost overall wellness. It is naturally very low in fat and sugar, meaning that it is cholesterol free and low in calories. Coconut water is a natural, isotonic beverage with the same level of electrolytic balance as we have in our blood. It is the “fluid of life” and can be injected intravenously in an emergency. The quality of coconut water always depends on coconut water processing.

What is Coconut Water Processing?

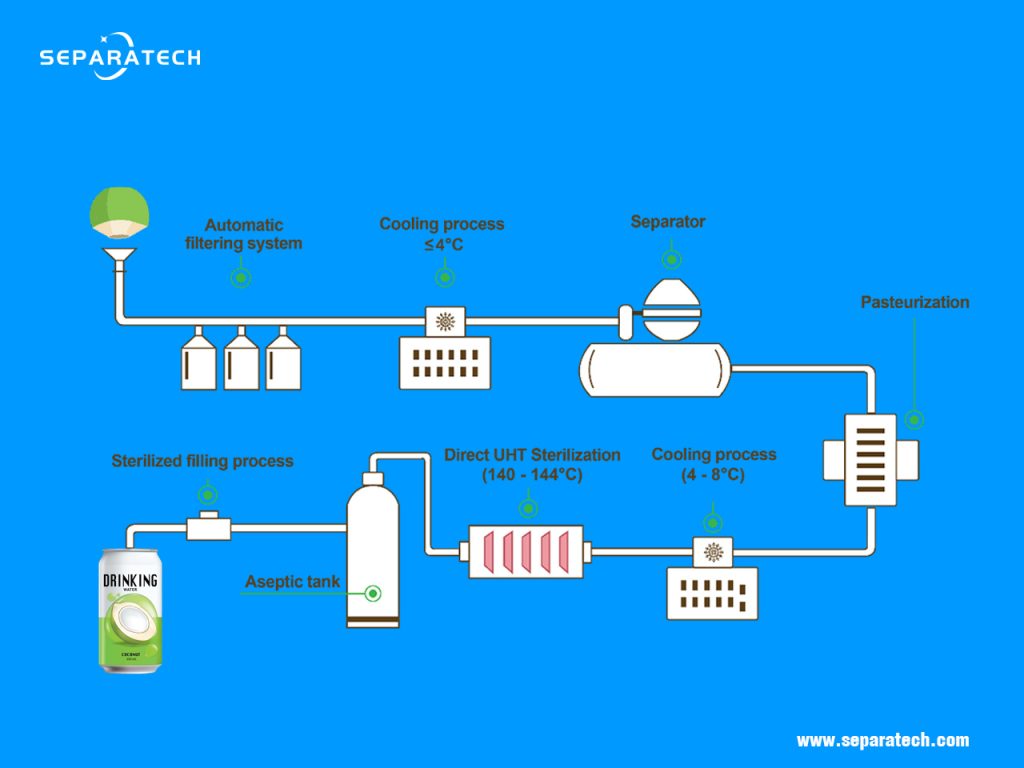

Coconut water processing refers to the methods used to extract, purify, and package coconut water for consumer use. The process begins with harvesting young coconuts, which are then opened to collect the liquid inside. To ensure a high-quality final product, it’s essential to remove impurities, sediments, and any unwanted particles that may affect the taste or safety of the drink. This is where disc separators come into play.

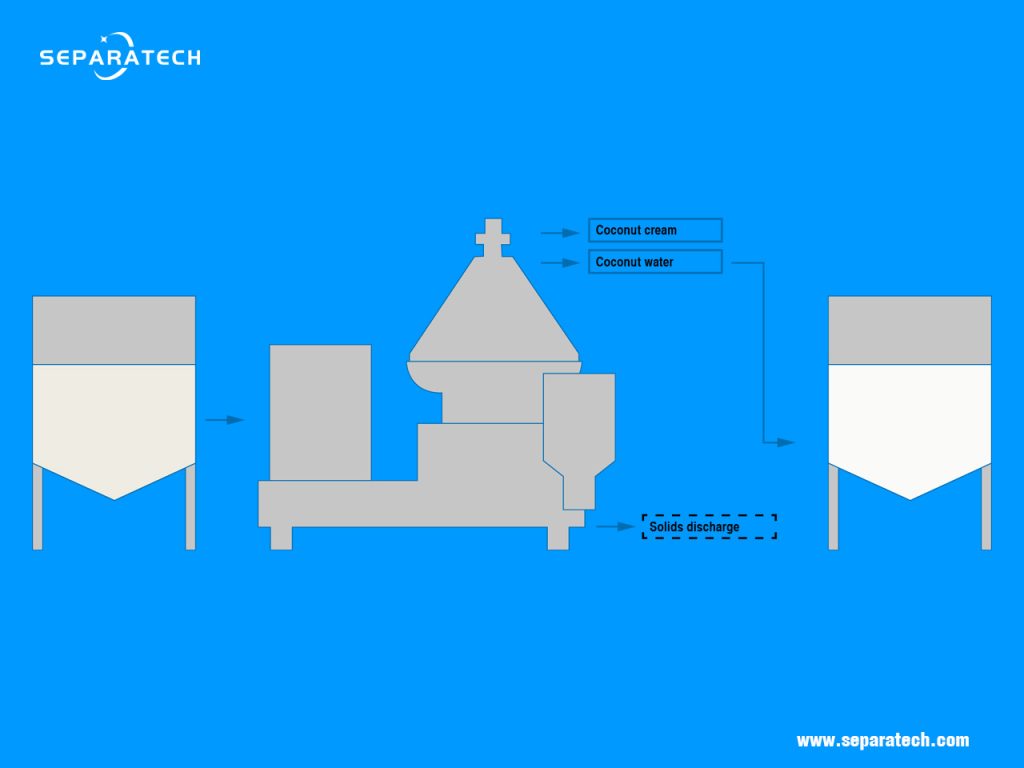

Coconut water processing flow chart

Working Principle of Disc Separator in Coconut Water Processing

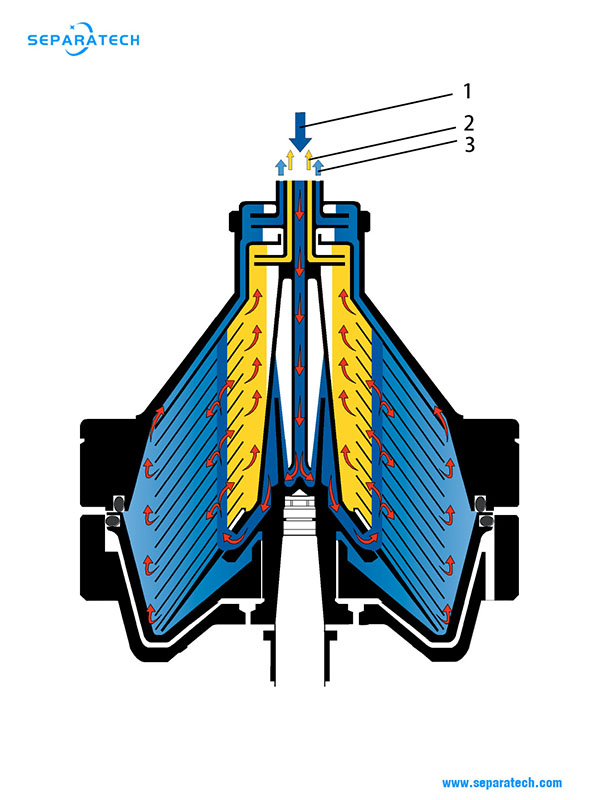

The raw coconut water to be separated is fed into the separator bowl from the feeding pipe at top, and enters the disc stack.

The coconut water phase and impurity solids phase are forced towards the periphery of the bowl, while the light coconut cream phase flows towards the centre of the bowl, from where it is pumped out for further processing. The coconut water phase is led over a top disc into a chamber where a centripetal pump pumps it out of the separator.

Solids collects in the sludge space and is discharged intermittently and automatically. The discharge is achieved by a hydraulic system, which at preset suitable intervals forces the sliding bowl bottom to drop down, thereby opening the sludge ports at the bowl periphery. The sludge is collected in the frame, and leaves the centrifuge via a cyclone.

The Role of Disc Separators in Coconut Water Processing

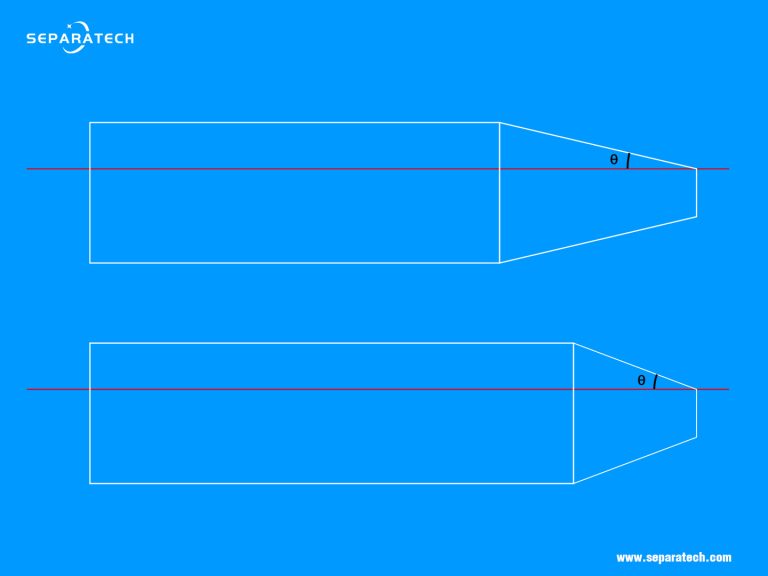

Disc separator, also known as disc stack centrifuge, are highly efficient devices designed to separate liquids from solids based on their density. In coconut water processing, they serve several critical functions:

1. Clarification: After the initial extraction, coconut water contains fine particles, fibers, and other impurities. Disc separators quickly and effectively remove these contaminants, resulting in a clearer and more appealing beverage.

2. Separation: These separators can also facilitate the separation of different liquid phases, such as oil and water, which may occur during processing. This ensures that only the purest coconut water reaches the packaging stage.

3. Efficiency: Disc separators are designed for high throughput, allowing processors to handle large volumes of coconut water quickly. This efficiency not only speeds up production but also reduces operational costs.

4. Quality Assurance: By providing consistent and reliable separation, disc separators help maintain the quality of the final product, ensuring that consumers receive a delicious and safe beverage.

Disc separator technical specifications

| Models | Capacity [L/h] | Motor [Kw] | Weight [Kg] |

|---|---|---|---|

| DKS10 | 600 | 4 | 500 |

| DKS30 | 2000 | 7.5 | 650 |

| DKS50 | 3000 | 11 | 1100 |

| DKS100 | 8000 | 22 | 1500 |

| DKS150 | 10000 | 30 | 2000 |

Conclusion

Coconut water processing is a vital step in bringing this nutritious beverage to consumers. With the efficiency and effectiveness of disc separators, processors can ensure that only the best coconut water makes it to market. For those looking to enhance their processing capabilities, investing in a disc separator from SEPARATECH is a smart choice.

SEPARATECH is a leading provider of disc separators and other centrifugation solutions. With years of experience in the field of coconut water processing, SEPARATECH offers a wide range of separators designed to meet the specific needs of coconut water processors. Their disc separators are known for their reliability, durability, and high-performance capabilities.

By investing in a high-quality disc separator from SEPARATECH, you can ensure the efficient and effective production of coconut water, meeting the increasing demand for this healthy and refreshing beverage. Experience the difference that high-quality centrifugation solutions can make in your coconut water processing today!