In the realm of edible oil refining, achieving the highest quality and purity of vegetable oils is paramount. Among the critical equipment used in this process, the vegetable oil centrifuge —also known as a disc stack centrifuge or vegetable oil separator—stands out for its efficiency and effectiveness.

The Refining Process and the Need for Centrifuges

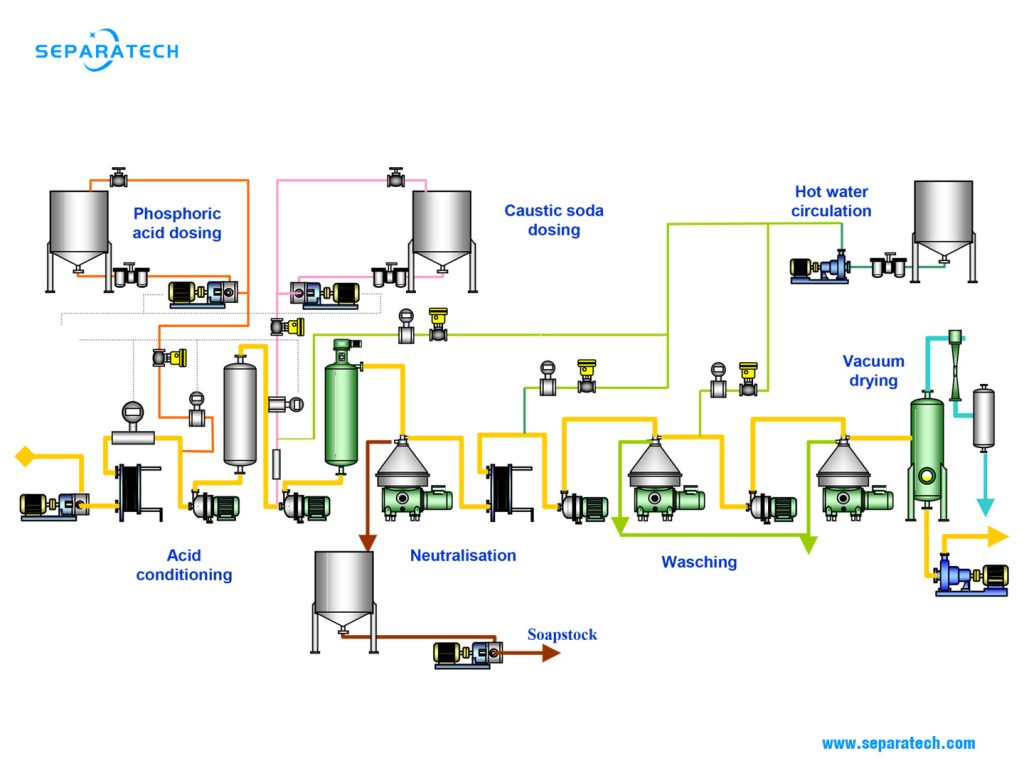

Vegetable oil refining involves several key steps, including degumming, neutralization, washing, bleaching, and deodorization. Each stage aims to remove impurities, free fatty acids, phospholipids, and other undesirable components to produce a high-quality oil suitable for consumption and industrial use.

Among these steps, degumming and neutralization are particularly crucial as they involve the separation of gums and soaps from the oil. This is where the vegetable oil separator plays an indispensable role. By utilizing centrifugal force, these separators efficiently remove impurities, ensuring the production of pure and stable oils.

Typical process:

– Soybean oil

– Peanut oil

– Canola oil

– Sunflower oil

– Animal fat

– Cottonseed oil

– Corn oil

– Fish oil

How Vegetable Oil Centrifuges Work

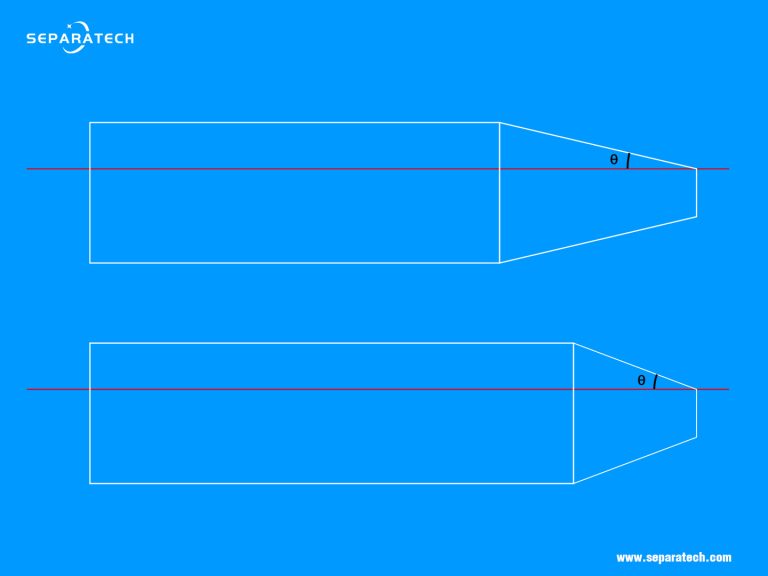

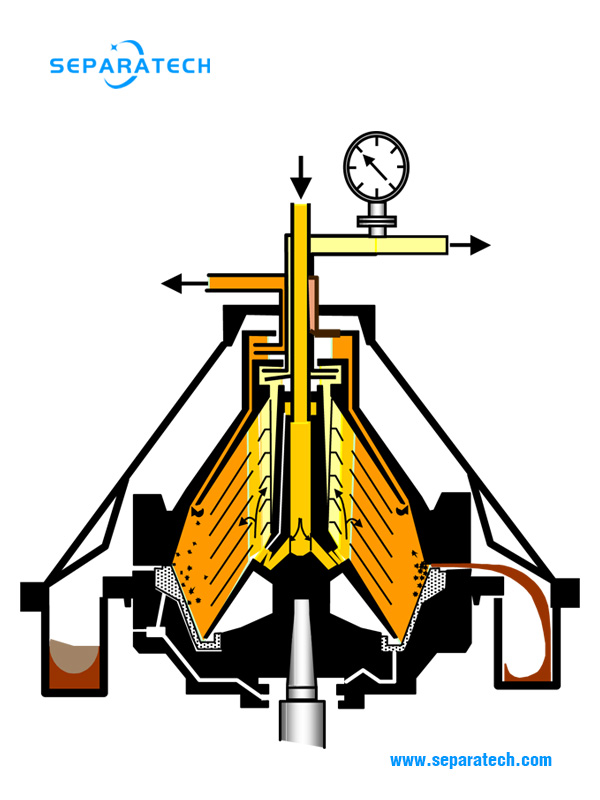

A vegetable oil centrifuge operates on the principle of centrifugal separation. Inside the machine, a stack of conical discs is arranged to form narrow channels. When the oil mixture is fed into the centrifuge, it is subjected to high-speed rotation. The centrifugal force generated causes the denser impurities and water to move outward towards the periphery, while the lighter, purified oil remains in the center.

The oil to be separated is fed into the separator bowl from the top through feeding pipe, and enters the disc stack. The heavy phase and heavy sludge are forced towards the periphery of the bowl, while the light phase flows towards the centre of the bowl, from where it is pumped out under pressure by a centriptal pump for further processing.

The heavy phase is led over a top disc into a chamber where an centripetal pump discharge it out of the separator under pressure. Sludge collects in the sludge space and is discharged intermittently and automatically, thanks to partial ejection and total ejection.

The sludge discharge is achieved by a hydraulic system, which at preset suitable intervals forces the sliding piston in the bowl to drop down, thus opening the sludge ports at the bowl periphery. The sludge is collected in the frame, and leaves the centrifuge via a cyclone.

The design of these centrifuges allows for continuous processing, ensuring high throughput and efficiency. The separated impurities and water are discharged from the centrifuge, leaving behind clarified oil ready for further processing.

Typical process flow of vegetable oil refining with disc centrifuge

Advantages of Using Vegetable Oil Centrifuges

1. High Purity and Quality:

The use of a vegetable oil centrifuge ensures the removal of impurities, resulting in oils with high clarity and stability.

2. Efficiency:

These centrifuges provide continuous processing, significantly reducing the time required for separation and refining.

3. Cost-Effectiveness:

By improving separation efficiency, vegetable oil separators minimize product losses and reduce operational costs.

4. Versatility:

Capable of handling various types of vegetable oils and impurities, these centrifuges are versatile and adaptable to different refining processes.

Features

– Self-cleaning bowl

– Enclosed feed and discharge

– Adjustable centripetal pump for optimizing separation zone

– Low running noise with enclosed solids discharge

– Worm wheel gear with VFD drive

– Automatic lubricating

– Explosion-proof available

– Inert gas blanking available

In the edible oil refining industry, the role of vegetable oil centrifuges cannot be overstated. They are crucial for producing high-quality, pure vegetable oils by efficiently separating impurities from the oil. SEPARATECH offer state-of-the-art centrifuges that cater to the diverse needs of the industry. By investing in these advanced separation technologies, refineries can ensure the production of superior oils that meet the highest standards of quality and safety.

Technical specifications of DHZ centrifuges

| Water degumming | Acid degumming | Neutralisation | Washing | Miscella refining | |

|---|---|---|---|---|---|

| DHZ360 | 30 (t/d) | 30 (t/d) | 30 (t/d) | 30 (t/d) | 20 (t/d) |

| DHZ470 | 50 (t/d) | 50 (t/d) | 50 (t/d) | 50 (t/d) | 30 (t/d) |

| DHZ500 | 150 (t/d) | 150 (t/d) | 150 (t/d) | 150 (t/d) | 100 (t/d) |

| DHZ550 | 300 (t/d) | 300 (t/d) | 300 (t/d) | 300 (t/d) | 180 (t/d) |

| DHZ700 | 450 (t/d) | 450 (t/d) | 450 (t/d) | 450 (t/d) | 200 (t/d) |

| DHZ830 | 800 (t/d) | 800 (t/d) | 800 (t/d) | 800 (t/d) | 500 (t/d) |