Cream separator for milk separation in Dairy Industry

Milk from the cattle contains a number of large and small butter-fat particles held in suspension. They are lighter in weight than the other parts of the whole milk. When milk is left standing, the milk portion low in fat (like skim milk) gradually settles at the bottom because it is heavier. On the other hand, butter-fat surfaces to the top through buoyancy. When the bulk of the fat globules find their way to the top, they constitute ‘Malai’ (like cream), which consists largely of the fat particles.

Why separate cream from milk?

All the commercial available cream is obtained by mechanical separation. Separation of whole milk produces two fractions. The fraction, which contains fat in highly concentrated form, is called cream while the other fraction, which is a non-fat fraction, is termed as skim milk. The fat content of cream can be varied, depending on the need, from 20 to as high as 80% fat. Cream is used for making ice cream, butter, ghee and Anhydrous milk fat in the dairy plants. Some portion of cream is utilized for dressing the product in bakery and coffee making. Cream can also be sold as ‘marketcream’ such as Table/coffee cream, whipping cream, single cream, double cream, cultured cream, etc.

Milk Cream Separator Separation Efficiency

Skimming efficiency is expressed as residual fat content in the skimmed milk. At rated capacity, SEPARATECH milk cream separators generally give a residual fat content lower than:

– 0.03% measured by GERBER method

– 0.05% measured by RÖSE-GOTTLIEB method

Separation of hot / warm milk

There is no exact limit for hot milk separation temperature. Generally, warm milk skimming defined as:

“Separation of milk at 45-65°C, leaving less than 0.05% fat in the skimmed milk with a cream fat content of approximately 40%”.

warm milk separation process

Raw milk of known fat content, free from air, should be fed to the milk cream separator at relatively constant temperature and capacity. A change in operating conditions will influence the skimming efficiency. Standardized cream and skimmed milk are the products leaving the milk cream separator. Sediment discharged from the milk centrifuge during separation may contain bacteria, leucocyte, hair, sand and similar. If the hot or warm milk separator is the first centrifugal clarification step in the dairy, the discharged sediment is not possible to recycle. The best way to dispose it is to sterilise it with steam and dump it.

Separation of whey

The purpose with whey separation is primarily to remove as much fat as possible from the whey. This improves the efficiency in the following

processing of the whey.

Whey separation process

For an efficient separation of fat most of the remaining cheese fines have to be removed before separation. Fines can be taken away by sedimentation in tanks, by filtering or by centrifugal clarification.

Whey, free from air and preferably from fines, should be fed to the milk cream separator, at relatively constant temperature and capacity. A change in operating conditions will influence the separation efficiency.

Whey cream and skimmed whey are the products leaving the milk cream separator. Sediment discharged from the centrifuge during separation consists of residual cheese dust and precipitated whey proteins. The best way to dispose it is to send it back to the milk farmers.

Working Principle of Milk Cream Separator

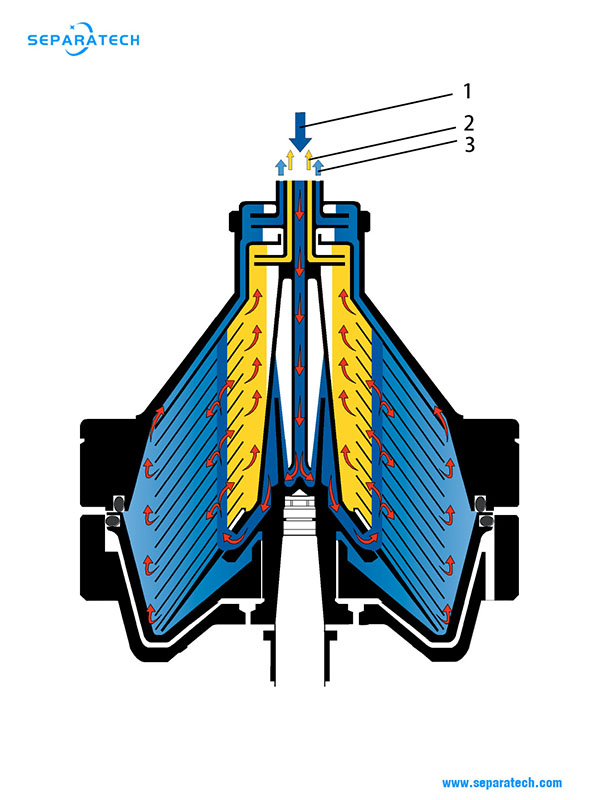

The milk cream separator is equipped with a self-cleaning disc-type bowl with hydraulically operated piston for opening and closing the sediment ejection ports of the bowl.

Milk or whey flows into the bowl through inlet and is separated into skimmed milk and cream in disc set. Both components are discharged without foam and under pressure by means of centripetal pumps through outlets.

The product is fed into and discharged from the bowl through a closed pipe system. There are no seals between the rotating bowl and the feed and discharge connections. The feed line is equipped with a flow constrictor to keep the feed rate constant. The skim milk and cream are discharged under pressure by built-in centripetal pumps, The pressure in the skim milk discharge line can be set by means of a pressure valve and a pressure gauge. The cream flowrate is set by means of a regulating valve fitted in the cream discharge line.

1. Feeding

2. Cream

3. Skim milk

Factors Affecting Separation and Skimming Efficiency

The factors that dictate the efficient separation process and ‘skimming efficiency’ (i.e. minimum loss of milk fat with skim milk) are as follows:

Temperature of separation: Separation temperature of 45-55°C has been found to give good results for a warm milk separator. Employing higher temperature ensures milk fat is in liquid condition, decreasing the viscosity of milk. Moreover, the difference in the density between fat and serum widens with rise in temperature.

Bowl speed: Skimming efficiency is quite adequate at moderate speeds of 4000-7000 rpm. It is important to maintain the bowl speed during operation. Hence, momentary deceleration that takes place during desludging operation should be restricted to minimum time period, since it can affect separation efficacy adversely.

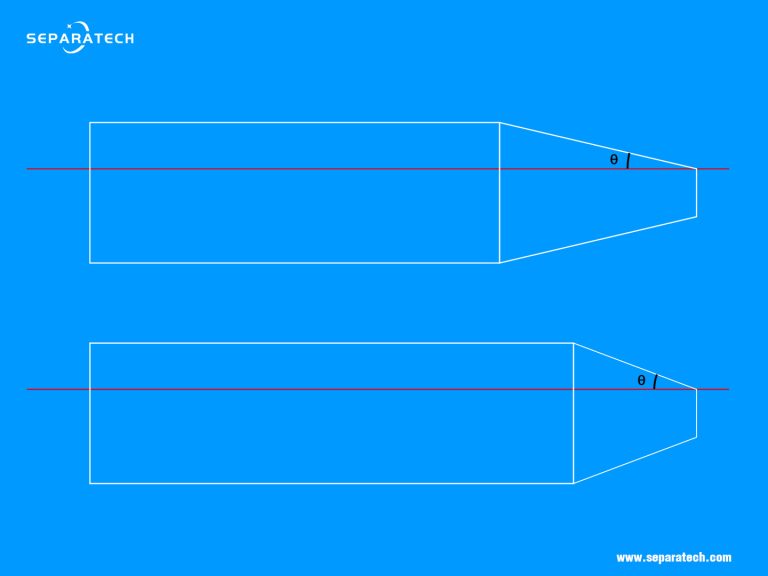

Space between the discs: Theoretically, smaller the space between discs, the higher should be the efficiency of separation. However, it is important to maintain laminar flow conditions to obtain maximum efficiency of separation. For narrow spacings (< 0.2 mm), separation efficiency is independent of disc spacing.

Flow of milk through the milk cream separator: Better efficiency can be achieved with lower input feeds, as milk has more time within the separator to allow fat globules to segregate. However, the flow should not be too low to allow air entrainment, which adversely affects separation efficiency. In practice, as high a flow rate as possible should be aimed for, keeping into mind the manufacturer’s directives.

Condition of the milk: The factors which affect fat globule size distribution are breed of animal, stage of lactation, temperature history of the milk and handling of milk through agitation, pumping, aeration, etc. Smaller fat globule size of fat would tend to escape the centrifugal force (i.e. < 1 mm). The milk to be fed to a hermetic separator should be free from air entrapment as far as possible.

Condition of the cream separator: The cream separator parts (especially discs) should be handled properly especially during cleaning and keeping after cleaning so as to avoid any scratches on it. The milk cream separator assembly has to be fastened to the base in such a manner that there is no vibration during the operation (rotation).

Cream Separator Technical Specifications

| Models | Skimming Capacity [L/h] | Standardization Capacity [L/h] | Motor [Kw] |

|---|---|---|---|

| DKS10 | 1000 | 1500 | 4 |

| DKS30 | 3000 | 4500 | 7.5 |

| DKS50 | 5000 | 7500 | 11 |

| DKS100 | 10000 | 15000 | 18.5 |

| DKS150 | 15000 | 22000 | 22 |

Cream separation is one of critical steps in dairy industry. Surplus fat from whole milk can be extracted in the form of cream, which can then be used to prepare fat-rich products like butter, ghee, anhydrous milk fat. Milk cream separator machine with self-cleaning bowl is the optimized solution for industrial milk separation, thank s to its high skimming efficiency and labor saving.