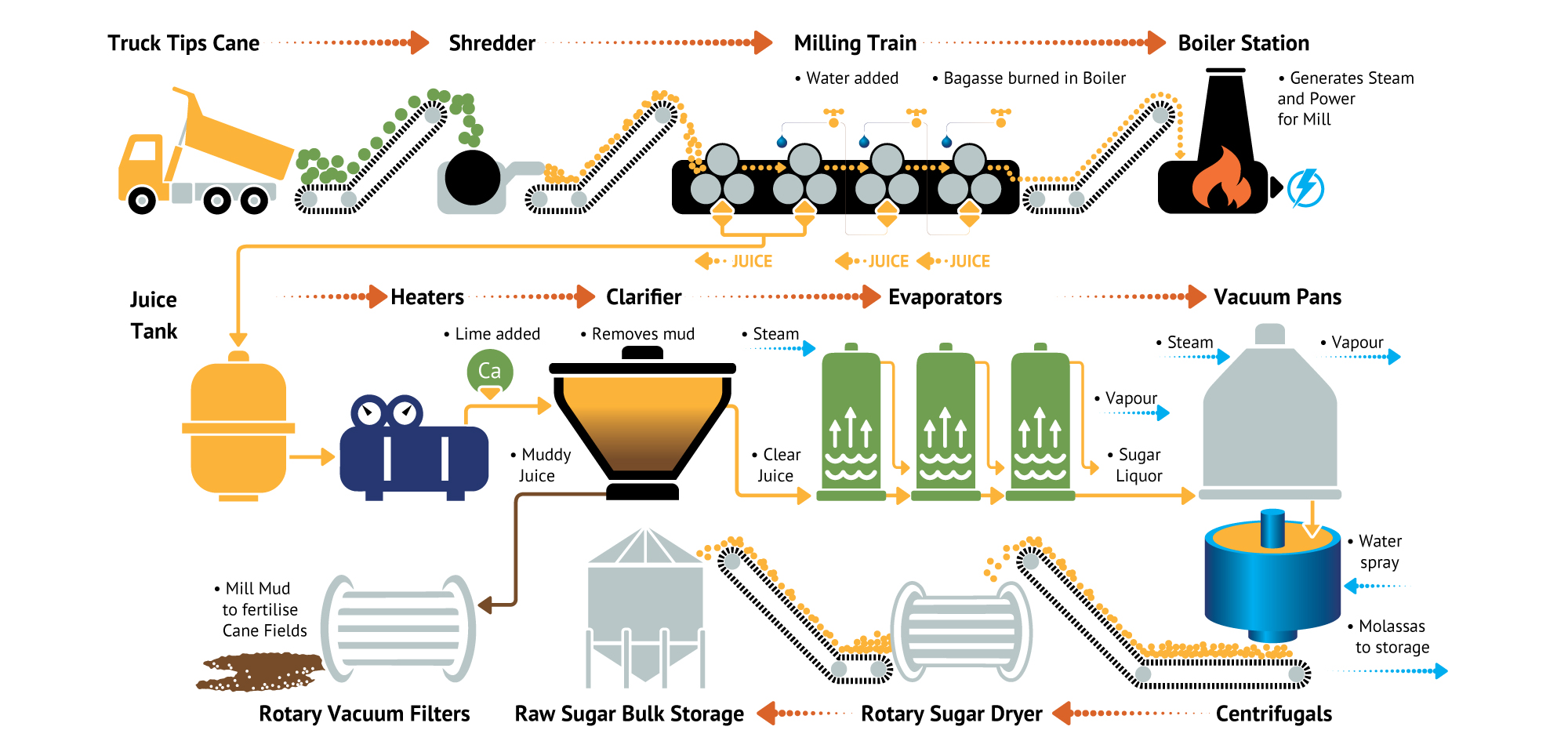

Sugar is a sweet, crystalline substance that is produced from sugar cane or sugar beets. The industrial production of sugar involves a number of steps, including:

1. Harvesting. Sugar cane and sugar beets are typically harvested from fields mechanically. They are then transported to the factory by trucks, railcars, barges, or trailers .

2. Washing and initial preparation. As soon as the sugar cane or sugar beets arrive at the factory, they are washed extensively to remove dirt and debris. They are then chopped into small pieces called cossettes for sugar beets or shredded for sugar cane .

3. Juice extraction. The cossettes or shredded cane are pumped into large tanks where hot water or steam is applied to extract the juice. The juice is then filtered to remove impurities and sent to the next stage .

4. Purification of juice. The juice is treated with lime and carbon dioxide to adjust its pH and remove unwanted substances such as organic acids, proteins, and minerals. The purified juice is then evaporated to concentrate the sugar content .

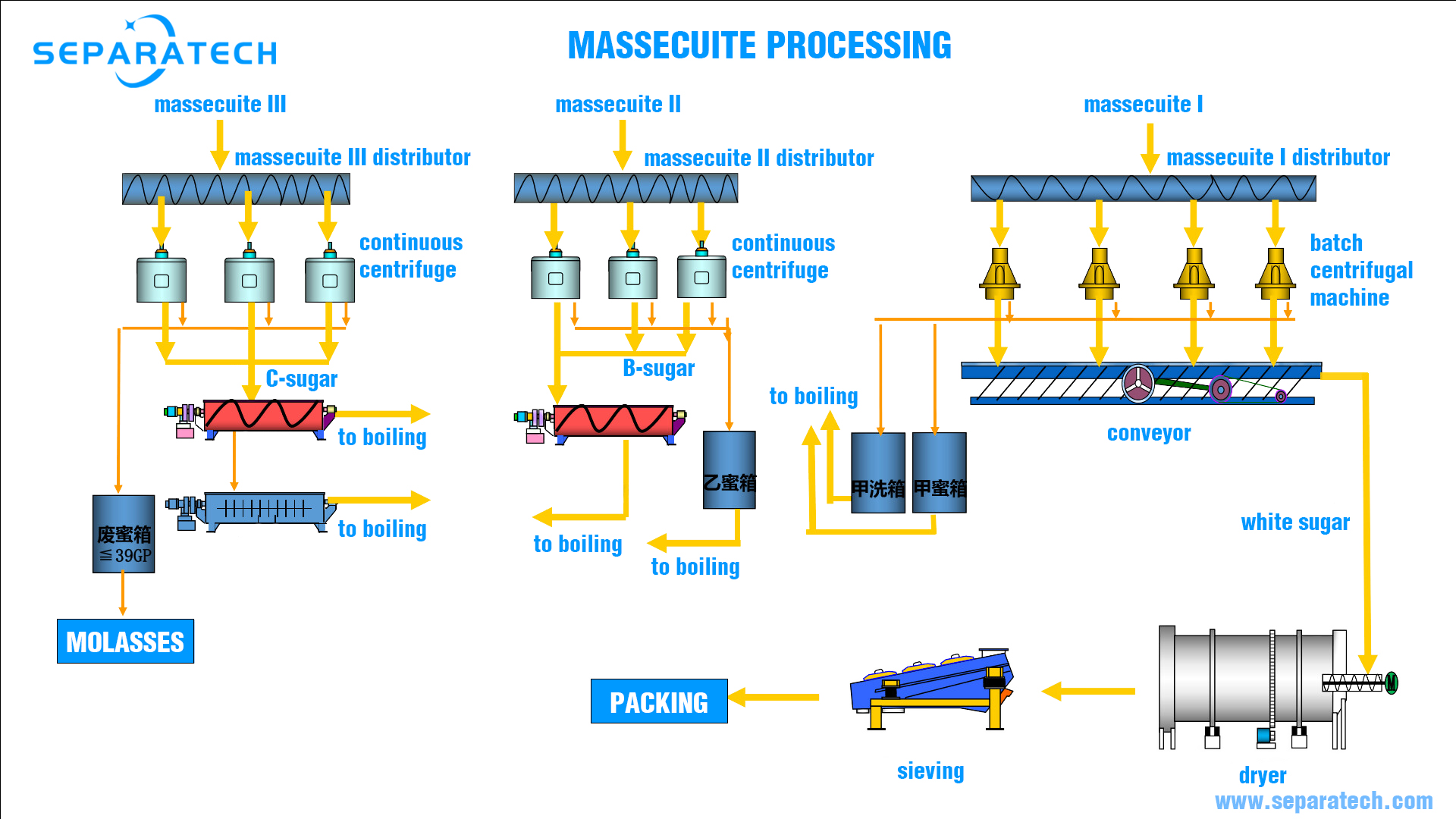

5. Crystallization. The concentrated juice is further boiled in vacuum pans to form a thick syrup called massecuite, which contains sugar crystals and molasses. The massecuite is then transferred to centrifuges for separation .

6. Centrifugation. This is the stage where batch centrifugal and continuous centrifugal machines are used to separate the sugar crystals from the molasses. Batch centrifugal machines are best for A sugars (the highest quality of white sugar) because they cause less crystal breakage and allow better control of the washing process . Continuous centrifugal machines are used for B and C sugars (lower grades of white sugar) because they are more efficient and can handle larger volumes of massecuite . The separated crystals are then dried and cooled before packaging .

7. Drying and packaging. The dried crystals are screened to remove dust and fines, and then packed in bags or bulk containers for storage or distribution.

The role of batch centrifugal and continuous centrifugal in massecuite processing:

Batch centrifugal: Batch centrifugals are used to separate the crystals from the syrup in the massecuite processing stage. The massecuite is a mixture of syrup and crystals that is produced during the crystallization process. The batch centrifugal spins the massecuite at high speed, which causes the crystals to separate from the syrup. The crystals are then collected and the syrup is recycled back into the process.

Continuous centrifugal: Continuous centrifugals are used to further refine the sugar crystals after they have been separated from the syrup in the batch centrifugal. The continuous centrifugal spins the crystals at even higher speeds, which removes any remaining impurities. The refined crystals are then collected and packaged for sale.

These are the main steps in industrial sugar production, with a focus on the role of batch centrifugal and continuous centrifugal machines in massecuite processing. If you have any questions or comments, please feel free to contact us.