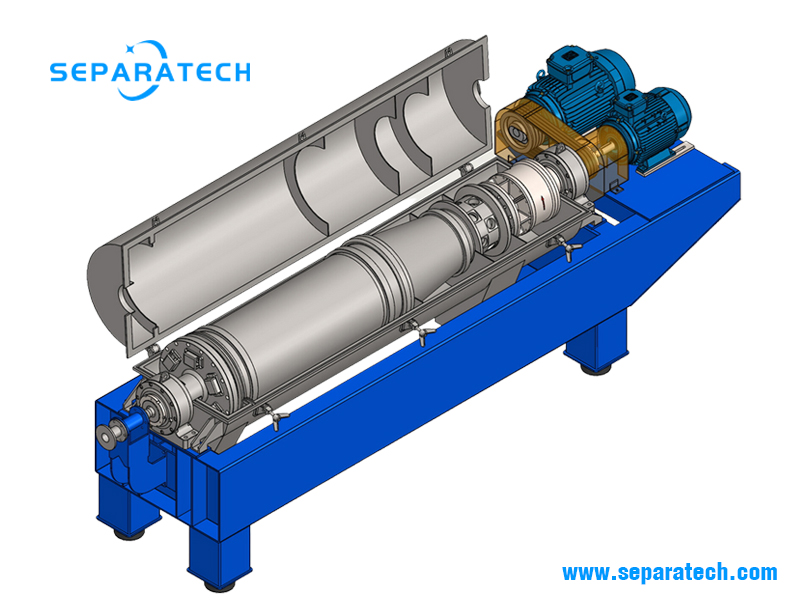

Separating Decanter Centrifuge

Separating decanter centrifuge, 3-phase decanter centrifuge, is mainly used for separating two immiscible liquids of different densities from each other, simultaneous removing solids.

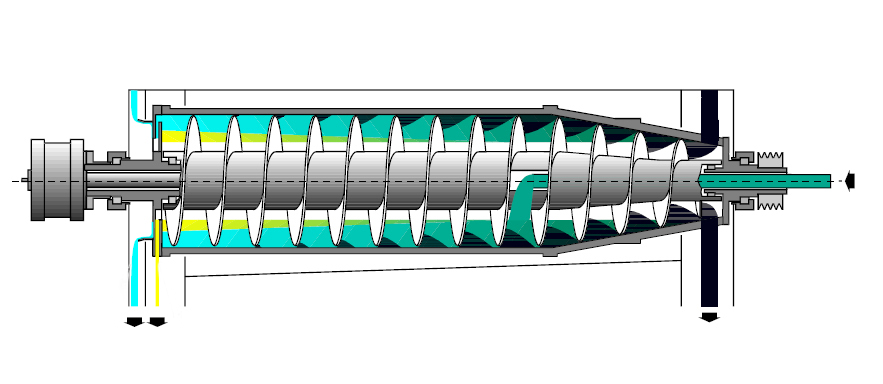

The light liquid phase is discharged into the casing through radial holes in the large end hub. The heavy liquid phase is discharged through axial holes in the large end hub. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The liquid level is controlled by plate dams. In order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub. The heavy liquid phase has to pass under the separating plate before being discharged into the casing. The liquid radius for the heavy liquid phase is controlled by plate dams. The solids are discharged under gravity.

Working principle of separating decanter centrifuge

The solid-wall bowl of separating decanter centrifuge has a cylindrical section for efficient separation and clarification of the liquids and a conical section for drying the solids.

The product enters the separating decanter centrifuge through the feeding pipe and passes through the distributor into the separation chamber. The liquid level in the bowl is adjustable via regulating tubes or overflow dam. Due to the centrifugal forces, the solid particles are flung onto the bowl wall. The hardfaced scroll conveys them to the solids discharge which is equipped with hard metal bushes. The solids are discharged under gravity.

The liquid phases are separated in the separation zone. The liquid radius for the light liquid phase is smaller than the radius for the heavy liquid phase. The layer thickness of the heavy phase is externally adjustable via regulating tubes or overflow dam. this changes the liquid level in the bowl. The light liquid phase moves in the direction of the bowl axis and is discharged under pressure via centripetal pump or under gravity. The heavy liquid phase moves in the direction of the bowl shell and is gravity discharged through regulating tubes or built-in impeller. In conventional design of separating decanter centrifuge, in order to prevent the light liquid phase from leaving the bowl through the heavy liquid phase outlet, a separating plate is placed on the inside of the large end hub.

Features of separating decanter centrifuge

Simultaneously separating liquid-liquid-solid mixture, which greatly saves energy consumption.

– Separating decanter centrifuge can handle a wide range of solids concentrations in feeding.

– Separating decanter centrifuge can flexibly respond to changes in the concentration of light-heavy liquid phases in raw materials

– When the liquid phase is discharged under pressure by the built-in centripetal pump, the downstream transfer pump is omitted.

Typical applications of separating decanter centrifuge

– Separation of oil sludge containing oil from refineries, oil ponds, etc.

– Extraction of animal/vegetable fats and oils

– Starch manufacture for separating wheat starch and gluten

– Oil water and solids separation

– Coal tar treatment

– Biofuel production

– Lubricating oil additives

– Meat/poultry/fish processing